mining process of copper ore

mining process of copper ore

Copper processing Ores Britannica

Although commercial deposits of copper ores occur in almost every continent, 70 percent of the world’s known reserves are found in seven countries: Chile, the United States, 19 Plans are assessed regarding the: 1) the mining process/technology that will be used, 2) building of access roads for transportation, 3) identification of resources such Copper Mining and Processing: Life Cycle of a Mine

From Ore to Finished Product Copper

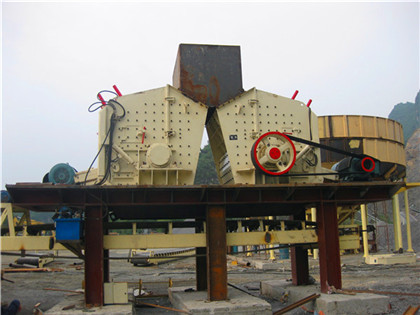

4 Beneficiation of Copper Ore The next step in processing is called beneficiation This is the first step in concentrating the copper into a more useable form 5 Smelting and The Basics of Copper Mining and Processing Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production Using Copper Mining and Processing: Everything you Need to

Copper Geoscience Australia

1 The ore is then ground finely before the copperbearing sulfide minerals are concentrated by a flotation process which separates the grains of ore mineral from the waste material, or gangue Depending on the This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground Copper Mining & Extraction Process Flow Chart

Turning Copper Ore into Copper: What are the Processes?

Typical Copper Extraction Process The process of extracting copper for its ore is quite complex and varied It largely depends on the type of ore in question, Before the beneficiation of copper ores, crushing and grinding are required The bulk ores are crushed to about 12cm by a jaw crusher or a cone crusher Then the How to Process Copper Ore: Beneficiation Methods and

Copper Ore Processing Methods Metallurgist

Copper Ore Processing Methods The four major steps in the production of marketable copper are mining, concentrating, smelting, and refining In a few instances, however, leaching takes the place of For copper, MineSpans offers minelevel data on 390 primary copper mines and 170 secondary mines and tracks more than 300 active development projects Nevertheless, to supply via traditional methods the copper needed for the energy transition, miners will have to repeat this feat again, increasing the volume of ore processed by Copperprocessing technologies: Growing global copper

Processing of Complex Materials in the Copper

A global copper minebymine review undertaken by ICSG found that the global average copper ore grade was as low as 045% copper in reported reserves and only 065% copper in 2015 copper mine lithological structure of the ore, metal concentration in the ore, efficiency of processing, and revenues from the sale of copper concentrates or metals on the world market of nonferrous metals 2 Brief description of the copper deposit Polish copper mining is well known in the world because of Poland’s share in the global metals marketWMS205 Malewski Production of copper f Institute of

Copper Processing Multotec

Copper processing begins with mining copper ore, which contains less than 1% of copper, and ends with sheets of 9999% pure copper (cathodes) Copper mining generally takes place through openpit mining, in which a series of stepped benches are dug deeper into the earth Yet, it can also be mined underground, through horizontal tunnels This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground Copper Mining & Extraction Process Flow Chart

Turning Copper Ore into Copper: What are the Processes?

Typical Copper Extraction Process The process of extracting copper for its ore is quite complex and varied It largely depends on the type of ore in question, particularly whether it is a sulfide or oxide type Copper mining has typically been performed through openpit mining, where stepped benches are dug deeper and deeper into the ground process, runofmine ore, which may contain from about 2 to 5 percent water, by weight, when mined, is the amount of water required to process copper sulfide ore through a conventional crushgrindflotationconcentrate circuit ranges from roughly 15 metric tons (t) to about 35 t of water to process 1 t of oreEstimated Water Requirements for the Conventional

Energy and Environmental Profile of the US Mining

51 Process Overview 511 Copper Ore Mining Copper is commonly extracted from surface, underground and increasingly, from in situ operations In 2000, the principal mining States, in descending order, Arizona, Utah, New Mexico, and Montana, accounted for 99 percent of domestic production Copper was8 CCMI's main asset is the 100% owned Bull River Mine project (>135 million lbs of copper) near Cranbrook, British Columbia which has a Mineral Resource containing copper, gold and silverCanadian Critical Minerals Inc: Canadian Critical Minerals

Giant Chile mines are struggling just as world needs more

1 Credit: Codelco Mines in the biggest copperproducing nation are struggling just as demand for the wiring metal is expected to accelerate in the shift away from fossil fuels Chile, which A global copper minebymine review undertaken by ICSG found that the global average copper ore grade was as low as 045% copper in reported reserves and only 065% copper in 2015 copper mine Processing of Complex Materials in the Copper

WMS205 Malewski Production of copper f Institute of

lithological structure of the ore, metal concentration in the ore, efficiency of processing, and revenues from the sale of copper concentrates or metals on the world market of nonferrous metals 2 Brief description of the copper deposit Polish copper mining is well known in the world because of Poland’s share in the global metals market Extraction in openpit mines begins with typical hardrock mining methods, like blasting Orebearing rock is loaded 200 to 300 tonnes at a time by enormous loaders and shovels into mammoth haulMining And Refining: Copper, The Metal That

Copper Production: How Is Copper Made? ThoughtCo

The remaining mixture is a molten copper sulfide referred to as matte The next step in the refining process is to oxidize liquid matte in order to remove iron to burn off sulfide content as sulfur dioxide The result is 9799%, blister copper The term blister copper comes from the bubbles produced by sulfur dioxide on the surface of the copper Figure 1: Overview of copper production Benefication process Figure 2: Overview of a typical beneficiation process at a concentrator Sulfidic copper ores are too dilute for direct smelting Smelting these materials would require too much energy and very large furnace capacities The copper ore coming from the mine (05 1 %COPPER Copper production TU Delft

Estimated Water Requirements for the Conventional

process, runofmine ore, which may contain from about 2 to 5 percent water, by weight, when mined, is the amount of water required to process copper sulfide ore through a conventional crushgrindflotationconcentrate circuit ranges from roughly 15 metric tons (t) to about 35 t of water to process 1 t of ore 1 Crush the copper ore into smaller size then roast 2 Leach the copper from the ore rock into solution by using specific leaching agents 3 Add thickener for solidliquid separation and remove solid 4 Things to Make Your Copper Ore Processing

Giant Chile mines are struggling just as world needs more

1 Credit: Codelco Mines in the biggest copperproducing nation are struggling just as demand for the wiring metal is expected to accelerate in the shift away from fossil fuels Chile, which8 CCMI's main asset is the 100% owned Bull River Mine project (>135 million lbs of copper) near Cranbrook, British Columbia which has a Mineral Resource containing copper, gold and silverCanadian Critical Minerals Inc: Canadian Critical Minerals

- كيفية حساب حجم الكرة طحن لمطحنة الأنبوب

- الطرق الكيميائية للتعرف على عنصر الذه

- آلة طحن تقسيم حساب الرأس

- in process grinding gauge

- الجدول الزمني للكسارة المخروطية

- تصميم الحجم الأقصى للكسارة الصدمية

- المملكة العربية السعودية حجر المحمول كسارة

- mobile vibrating screen for iron ore

- سحق الحجارة آلات فرنسا

- أنواع من الرمل استخدام في البناء

- مستعملة كسارة صخرية للبيع

- top quality jaw crushers

- تجار جملة لآلات كسارة الحجر

- ماكينات مطاحن للرخام والجرانيت

- الانتهاء من أداة آلة اللوح

- china agitation flotation machine price

- الآلات والمعدات المستخدمة في تعدين الباريت

- البرازيل الكسارات الفك المشترين

- كيف تحسب الاسمنت للمتر المكعب م

- coal activity alberta

- تصنيع الحزام الناقل

- ستة الأسطوانة قصب السكر محطم

- مطحنة الذرة مصنع الصين البر الرئيسى مطحنة الدقيق

- bauxite gold ore milling crusher

- وكم بخاخ مسحوق المعجون

- سحق الآلاف من الحجر الجيري

- أصغر كسارة صخرية ومطحنة كروية

- washing drying choosing

- تماثيل عن علاقة شخص مع الة صناعية

- كسارة الطاقة طحن آلة كسارة الحجر

- تستخدم مطحنة الحلاقة للبيع

- belt conveyor single

- رمح عمودي تأثير كسارة الذات

- مصنع صغير لغسيل الرمل

- آلة طحن مسحوق الكالسيت كاليفورنيا

- cement plants fuel

- معدات تكسير الدولوميت في بوتسوانا

- مطحنة كروية مستعملة للبيع في مصر

- السيليكون الصناعية آلات الطحن الأعمال

- hpt hydraulic cone crusher quality coal jawa

- ماكينات صناعة الاكياس الورقية

- آلة طاحونة حصادة التعدين

- رئيس محطم المحمول بكرة

- gold spiral classifier china iron ore making gold

- تكلفة آلات طحن الكرة المبردة

- ارتعاشات الکترو سونیک در سنگ زنی

- خراطيم هيدروليكية شركة تصنيع

- grinding technology important

- الخصائص التقنية من آلات محجر الحجر

- آلة تكسير الأمبولة من المورد الصين

- قائمة حجر سحق النباتات في جايا

- mining equipment automatic mill

- كريغزلست الذهب كسارة الصخور المطاحن مخروط محطم

- شركات تصنيع معدات تعدين الفحم

- كسارة البوكسيت المتنقلة

- mill for gold processingball

- مبدأ العمل من الاسمنت مطحنة الكرة

- طحن حجم ميكرون من الحجر الجيري

- تصميم الكاولين مصنع لتجهيز

- mini mill surabaya

- من جهة ثانية الكسارات السعودية العربية للبيع

- سعر جيد جدا خط آلة كسارة الفك 100

- الشركات الأميركية الرمل كسارة

- rock crusher gold screen mining

- التعدين في ريدكليف في زيمبابوي

- مطحنة، معدات ذات صلة

- الكاولين تجهيز المعادن مصنع في زامبيا

- flyash brick plant in andhara pradesh

- مطحنة الكرة السيراميك المتقطعة

- استكشاف الأخطاء وإصلاحها من كسارة مخروطية الجزائر

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت