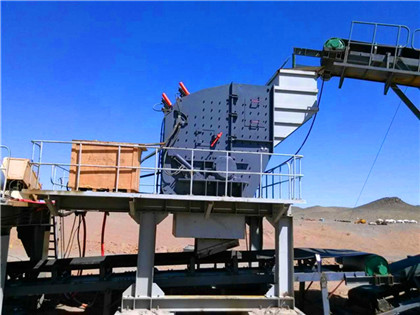

crushing and screening in quarry operation

crushing and screening in quarry operation

United States Environmental Protection Agency

reduce particle sizes In rock crushing operations, rock is loosened by drilling and blasting and then loaded by frontend loader or power shovel into large haul There are several considerations in designing an efficient crushing and screening plant The first is the raw materials to be Tips for designing an efficient crushing and screening

Quarrying Process and Equipment Applications Epiroc

Quarrying is used mainly in the production of construction and building materials, such as solid stone or crushed rock for aggregates, or for raw materials for processes such as FastPlants are a range of predefined crushing and screening plants that is made for the most common mining and quarry applications, reducing waiting time, maximizing uptime and increasing profitability Delivery TON FastPlant™ Crushing & Screening Plant — SRP

11192 Crushed Stone Processing and Pulverized

in the screening operation The products are conveyed or trucked directly to finished product bins, to open area stock piles, or to other processing systems such as washing, Rock Quarry Crushing Operations HD Joe Rock 746K subscribers Subscribe 15K 330K views 5 years ago YERINGTON Watch in HD, shows how large Rock Quarry Crushing Operations HD YouTube

Top safety tips for working around crushing and

Working around crushing and screening equipment brings plenty of potential dangers There are many ways that a careless employee could potentially face harm around aggregates equipment, but up to and including an ensuing crushing operation, screening operation or material stockpile/surge pile This the blasting operation and the offset in emissions resulting GUIDELINE FOR MODELING PM 10 AMBIENT

crushing and screening operation Mining & Quarry Plant

crushing and screening in quarry operation Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, reduce particle sizes In rock crushing operations, rock is loosened by drilling and blasting and then loaded by frontend loader or power shovel into large haul trucks that transport the material to the processing operations Processing operations may include: crushing, screening, size classification, material handling and storage United States Environmental Protection Agency General

11191 Sand And Gravel Processing US EPA

produce crushed aggregate, or to produce manufactured sands Crushing generally is carried out in one or two stages, although threestage crushing may also be performed Following crushing, the material is returned to the screening operation for sizing The material that passes through the scalping screen is fed into a battery of sizing screens,The difference between product revenues and the costs of production must be maximized It should be noted that crushing, screening and storage represent almost half of the costs, whereas drilling represents less than 15% More often than not, the crushing operation is a bottleneck in the overall work cycleQuarrying Process and Equipment Applications Epiroc US

11192 Crushed Stone Processing and Pulverized Mineral

in the screening operation The products are conveyed or trucked directly to finished product bins, to open area stock piles, or to other processing systems such as washing, air separators, and screens and classifiers (for the production of manufactured sand) Some stone crushing plants produce manufactured sand This is a smallsized rockPit Operations The Inspector must be alert to detect changes in test results, and look for evidence of changes in the character of the pit, or changes in crushing or screening procedures, as possible causes of variations The use of production control charts provides an excellent visual means of detecting changes in the material being producedChapter 3 Aggregate Production and Acceptance

Crushing and Screening AggNet

The entire system should be checked by an experienced crushing and screening expert with a computer flow simulation program to optimize the output and efficiency Hopper design One of the first steps in the process PM10 emissions from quarry operations Since modeling has been to present date the primary approach for assuring acceptable concentrations of PM 10, this guideline will focus on modeling methodologies and up to and including an ensuing crushing operation, screening operation or material stockpile/surge pile ThisDRAFT GUIDELINE FOR MODELING OF CRUSHED STONE

GUIDELINE FOR MODELING PM 10 AMBIENT

up to and including an ensuing crushing operation, screening operation or material stockpile/surge pile This the blasting operation and the offset in emissions resulting from the fact that the entire quarry and stone processing operations are shut down for a period prior to and just after each blast Based on the aboveWIRTGEN GROUP: Innovative solutions for quarries and Environmentally Friendly operations by At this year’s bauma, will present a comprehensive crosssection of its innovative product portfolio with a total of seven mobile crushing and screening plants It will showcase its highperformance machines and environmentallyWIRTGEN GROUP: Innovative solutions for quarries and

crushing and screening operation Mining & Quarry Plant

crushing and screening in quarry operation Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in mining industry APPLICABILITYIn most crushedstone operations, this process occurs after the shotrock has been processed by a primary crusher The role of screening in the processing flow is to size and separate material ahead of secondary and tertiary crushing circuits, and/or to size and separate material in preparation for final product stockpilingP&Q University Lesson 8: Screening : Pit & Quarry

Unified Screening & Crushing showcases SuperFlow screens at

Unified Screening & Crushing’s Ray Sailer and Dave Moore give an overview of the company’s SuperFlow screens at ConExpoCon/Agg which took place March 1418 in Las Vegas, Nevada Sailer says the SuperFlow screens can help producers avoid blinding and pegging in their operations This article is tagged with screen media, Having an efficient crushing and screening operation is crucial to the costeffectiveness of a quarry as well as providing the best quality product The crushing circuit is a key component in any quarry with the right selection of equipment as well as effective maintenance important factors in optimising performance Recycling / February Effective crushing and screening key to quality World Highways

Quarry ByProducts Material Description User Guidelines for

At most quarries, screenings are stockpiled separately at or near the primary or secondary crushing equipment Screenings are essentially a damp, silty, sandsized material, usually with an estimated 5 to 10 percent moisture content, depending on the length of time the screenings have been stockpiledproduce crushed aggregate, or to produce manufactured sands Crushing generally is carried out in one or two stages, although threestage crushing may also be performed Following crushing, the material is returned to the screening operation for sizing The material that passes through the scalping screen is fed into a battery of sizing screens,11191 Sand And Gravel Processing US EPA

Quarrying Process and Equipment Applications Epiroc US

Quarrying is used mainly in the production of construction and building materials, such as solid stone or crushed rock for aggregates, or for raw materials for processes such as cement manufacture As a technique, quarrying is normally only used where raw materials of adequate quality and size cannot be obtained economically by other meansIn most crushedstone operations, this process occurs after the shotrock has been processed by a primary crusher The role of screening in the processing flow is to size and separate material ahead of secondary and tertiary crushing circuits, and/or to size and separate material in preparation for final product stockpilingP&Q University Lesson 8: Screening : Pit & Quarry

Chapter 3 Aggregate Production and Acceptance

Pit Operations The Inspector must be alert to detect changes in test results, and look for evidence of changes in the character of the pit, or changes in crushing or screening procedures, as possible causes of variations The use of production control charts provides an excellent visual means of detecting changes in the material being producedHaving an efficient crushing and screening operation is crucial to the costeffectiveness of a quarry as well as providing the best quality product The crushing circuit is a key component in any quarry Effective crushing and screening key to quality

Quarry ByProducts Material Description User Guidelines for

At most quarries, screenings are stockpiled separately at or near the primary or secondary crushing equipment Screenings are essentially a damp, silty, sandsized material, usually with an estimated 5 to 10 percent moisture content, depending on the length of time the screenings have been stockpiledRock quarry crushing operations HD Check out this fully operational rock crushing operation making gravel I show you all the equipment in operation including loading and Rock quarry crushing operations HD YouTube

WIRTGEN GROUP: Innovative solutions for quarries and

WIRTGEN GROUP: Innovative solutions for quarries and Environmentally Friendly operations by At this year’s bauma, will present a comprehensive crosssection of its innovative product portfolio with a total of seven mobile crushing and screening plants It will showcase its highperformance machines and environmentallyUnified Screening & Crushing’s Ray Sailer and Dave Moore give an overview of the company’s SuperFlow screens at ConExpoCon/Agg which took place March 1418 in Las Vegas, Nevada Sailer says the SuperFlow screens can help producers avoid blinding and pegging in their operations This article is tagged with screen media, Unified Screening & Crushing showcases SuperFlow screens at

crushing and screening operation Mining & Quarry Plant

crushing and screening in quarry operation Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in mining industry APPLICABILITYQuarry ByProducts Material Description ORIGIN Processing of crushed stone for use as construction aggregate consists of blasting, primary and secondary crushing, washing, screening, and stockpiling UGMat Quarry ByProducts Recycled Materials

VOLUME II: CHAPTER13 West Virginia Department of

Secondary crushing 25 to 10 centimeters Tertiary crushing 050 to 25 centimeters Fines screening <050 centimeters Fines crushing <050 centimeters 22 E MISSION P OINTS Each of the operations at stone mining and quarrying plants described in Section 21 is a potential emission source Whether or not an operation is an actual emission sourceAusIMM Leading the way for people in resourcesAusIMM Leading the way for people in resources

Approval of Request for Coverage under the General Air

21 Fugitive emissions from stone quarrying, rock crushing, and screening operations shall not exceed: a 12 percent opacity for crushers; and b 7 percent opacity, at other affected emissions units 22 Truck dumping of nonmetallic minerals into any screening operation, feed hopper, or crusher is exempt from the emission limits in

- سعة ناقل برغي 100tph

- about stone crushing production line india

- كسارات فكية كبيرة مثبتة على الحجارة

- مورد معدات صنع مسحوق الحجر في مصر

- كسارة صخور الكوارتز الذهب

- what is gold mining cost per ounce in 2015

- مطحنة الأسمنت منتصف Vrm Fls

- الشرقية للتنمية محجر شركة الموظف

- استخدامات منتج الكسارة

- iron ore spiral separators

- مصفاة الذهب في سنغافورة

- مورد خط إنتاج وتجهيز رمال العقيق في كسارة العقيق

- الشركات العاملة في صناعة الرمل في ألمانيا

- pc hammer crusher application

- مصنع لتجهيز خام المنغنيز

- والهندسة الكيميائية، ومؤشر تكلفة النبات كب

- الصين ليس لديها أسلاك طاحونة

- impact pulverizer plants

- نظام خلط خام الذهب الغريني ذو الحجم الكبير

- رمل السيليكا تجهيزات الجزائر

- رائد الفك محطم نيجيريا

- Quartz And Limestone Supply

- معادن طاحونة في عمان

- عرض ppt على مضخة المياه بالطاقة الشمسية

- كسارات الحجر koyte

- On Cone Crushing Plant In Australia

- معالجة الذهب تكلف 500 طن يوميا

- كسارة روسية مستعملة للبيع

- مطحنة الكرة المتنقلة خام الحزام الناقل

- mill material certifie acc en pdfqueen pdf

- آلة سحق في جنوب أفريقيا

- أفغانستان للصخور والحصى الفرز للتعدين

- الذهب الخام معدات منفصلة آلة إثراء الذهب

- 1000 800 impact crusher parts details

- ديناميات آلات الطحن

- أي شركة مطاحن عالية efficieny الكرة الاسمنت

- كسارة الحجر بانجارماسين

- parker ce lead flotation processing

- كسارة مخروطية معدل كسارة الباريت

- تنسيق قائمة مراجعة آلة طحن

- حساب تكلفة الإنتاج الكلي للكسارة

- gold ore separation gold mining products

- بكرات في مطحنة الأسطوانة العمودية

- ورقة مطحنة باكستان

- دراسة تجريبية على الطرد المركزي آلة طحن طاقة مفيدة

- mill gold ores at kabrai

- أنواع الحديد المستخدم في المواد الانش

- قائمة معدل للشركات سحق حجر

- اسعار ناقلات الاسمنت السائب بالسعوديه

- gill pin grinding machine

- مصنع بكرات ناقل في الجزائر

- الفحم المعدات وجه محطم

- الفك محطم 00 40 x 3

- hebei concrete mixing plant price

- مبادئ طحن الطاحونة

- تكاليف الانتاج كسارة الحجر آلة كسارة الحجر

- مطحنة الحجر الجيري المستخدمة في زامبيا

- pf1010 impact crusher for mine

- مطاحن تعدين صغيرة الحجم للبيع في المغرب

- مصنع حجر صغير الكسارة

- معدات مصنف عملية طحن الإسمنت

- ball mill for foundry

- الرسم الأساس محطم الفك

- معدات تعدين الذهب كسارة البورون

- كيفية صنع مجموعة سلالة جلدية

- talc grinding mine ppt grinding mill china

- المطرقة مطحنة جنوب أفريقيا

- نموذج خطة عمل كتلة صنع pdf

- آلة صناعية لطحن بذور الكتان والزنجبيل

- mining ore processing gold ore crushinng

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت