parker ce lead flotation processing

parker ce lead flotation processing

Critical importance of pH and collector type on the

The schematic process flow diagram of actual flotation plant Full size image In both lead and zinc circuits, pyrite is the main sulphide gangue mineral It is Solvay’s flotation collectors are specifically designed according to mineralogical needs to enhance throughput, grade and recovery They can provide superior kinetics and work HighPerformance Flotation Collectors Solvay

(PDF) Pb Flotation Lead Flotation ResearchGate

Abstract Flotation of lead ores Reagents used Princibles of PbS flot Process parameters of Pb flotation Floc flotation Pb ores Flowsheets and reagent Conventional sulfidizationflotation is regarded as the most efficient processing method for copper or lead oxide ores; however, it is still inefficient for A successful operational initiative in copper oxide

Declaration Pressure Equipment Directive (PED) 2014/68/EC

Parker Hannifin Manufacturing Germany GmbH & Co KG Fluid Connectors Group Europe High Pressure Connectors Europe Am Metallwerk 9 D33659 2way slipin cartridge valves series CE and CP are hydraulically controlled seat valves which are universally applicable The complete modular system covers all sizes2Way SlipIn Cartridge Valve Series CE, CP Parker NA

How to Process LowGrade Lead Zinc Ore by Flotation

The jig discharges into a 6 cell No 24 “SubA” Flotation Machine which produces a highgrade lead concentrate which is dewatered in a Thickener A Adjustable The recovery of silver minerals occurring in a leadzinc sulfide ore is efficiently accomplished using the above flowsheet The process consists of selective Silver Lead Zinc Ore Processing Method using Flotation

Flotation data for the design of process plants Part 2 case

a combined or bulk lead, zinc, silver, gold and copper product for processing in Imperial Smelter Furnace smelters The four product ßowsheet produced individual products of Zero loss mechanical float condensate drains for industrial compressed air and biogas treatment applications To the extent that Parker or its subsidiaries or authorized HDF Series Zero Loss Mechanical Float Condensate Drain

Critical importance of pH and collector type on the flotation of

Collector type and pulp pH play an important role in the lead–zinc ore flotation process In the current study, the effect of pulp pH and the collector type parameters on the galena andFroth flotation is the most widely used beneficiation technique The selection of a suitable reagent regime in view of varied mineralogy, physical and chemical characteristics of leadzinc ore is of critical importance Beneficiation of LeadZinc Ores A Review: Mineral Processing

(PDF) Pb Flotation Lead Flotation ResearchGate

Reagents used Princibles of PbS flot Process parameters of Pb flotation Floc flotation Pb ores Presentation PDF Available Pb Flotation Lead Flotation January 2021; DOI:1013140/RGAs part of the industrial performance verification, with the permission from M/s Vedanta to conduct the plant trial runs, a 5 m 3 BQR flotation cell with MAXGen mechanism was designed, manufactured, and placed parallel to the existing 5 m 3 cleaner3 cell in the lead circuit (in Stream3) at RampuraAgucha plant, Hindusthan Zinc Limited Plant Trials of the MAXGen Flotation Mechanism in a Lead Flotation

Mineral Processing and Metallurgical Treatment of

processing plant for flotation of lead, zinc, and va nadate minerals was introduced by the end of 1961 and closed in 1978 The processing plant with a total capacity of 8000 tons monthly was diviHowever, the number of papers that treated PbZn flotation process as MCDM problem is minor compared to the number of papers devoted to physicochemical reactions and kinetics in the froth flotation process As an example of these rare papers, Kostovic and Gligoric (2015), and Savic et al (2015) can be mentionedSelection of leadzinc flotation circuit design by applying

The Definitive Guide to Flotation Separation Fote Machinery

The flotation separation process mainly includes: (1) Grind the ore finely by the ball mill or rod mill to dissociate useful minerals from gangue minerals (2) Separate the ore by the flotation machine Adjust the ore pulp and add flotation reagents (3) Do the flotation processing (4) Filter, concentrate or dry the product of sphalerite as composite particles during lead flotation, and (c) the pulp pH was best maintained at natural pH during preflotation and at an elevated alkaline pH (pH 95) during lead flotation for optimal selectivity In terms of depressants it was found that zinc sulfate specifically depressed sphalerite during lead flotationThe Depression of Sphalerite during Carbon Preflotation

Lead Zinc Mining Solution & Equipment Mineral Processing

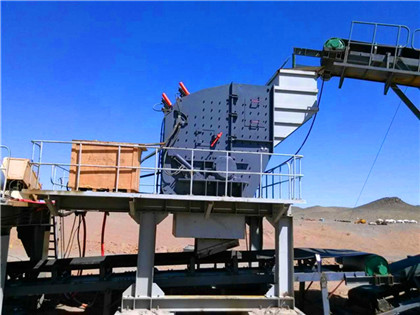

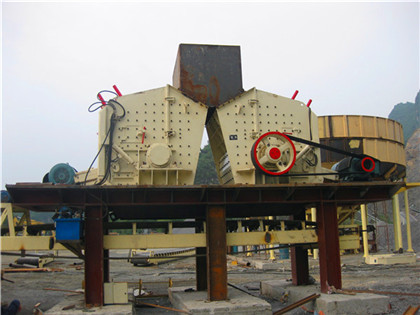

Generally, lead zinc flotation processing plant main process divided into three stages: crushing and screening grinding flotation separation concentate and dewatering 1Crushing & Screening: The crushing operation mostly adopts a twostage closedcircuit crushing and screening processThe flotation process was developed on a commercial scale early in the 20th century to remove very fine mineral particles that formerly had gone to waste in gravity concentration plants Flotation has now become the Flotation ore dressing Britannica

Effect and mechanism of potassiumpermanganate strengthening

To achieve the flotation separation of chalcopyrite, galena, and other minerals from sphalerite, depressants are needed Due to the difficulty of activation after the depression of galena andAggregation of the metallic concentrate is initiated in the flotation bath, where flocculation agents such as alum and lime help increase the average size of particles; xanthate is also added to the froth to help float the particles to the Lead processing Mining and concentrating Britannica

Froth flotation process and its application Wiley Online

The paper is about the froth flotation process and its application It is a metallurgical process for the extraction of metals in a pure state from their ores: especially for sulfide ores galena surface might be elemental sulfur or lead polysulfide[8] H 3 SURFACTANTS The surface of the solid that is to be floated must haveIn this study, we investigate a lowgrade oxidized lead ore containing noble metal silver, with complex mineralogy The sulfurization behaviors of different types of leadsilver minerals at different pH values were analyzed using the chemical phase analysis method The interactions between different types of leadsilver minerals and different Sulfidizing Behavior of Complex LeadSilver Ore: A Flotation Study

Critical importance of pH and collector type on the flotation of

The schematic process flow diagram of actual flotation plant Full size image In both lead and zinc circuits, pyrite is the main sulphide gangue mineral It is critical to decrease theReagents used Princibles of PbS flot Process parameters of Pb flotation Floc flotation Pb ores Presentation PDF Available Pb Flotation Lead Flotation January 2021; DOI:1013140/RG(PDF) Pb Flotation Lead Flotation ResearchGate

Plant Trials of the MAXGen Flotation Mechanism in a Lead Flotation

As part of the industrial performance verification, with the permission from M/s Vedanta to conduct the plant trial runs, a 5 m 3 BQR flotation cell with MAXGen mechanism was designed, manufactured, and placed parallel to the existing 5 m 3 cleaner3 cell in the lead circuit (in Stream3) at RampuraAgucha plant, Hindusthan Zinc Limited processing plant for flotation of lead, zinc, and va nadate minerals was introduced by the end of 1961 and closed in 1978 The processing plant with a total capacity of 8000 tons monthly was diviMineral Processing and Metallurgical Treatment of

Selection of leadzinc flotation circuit design by applying

However, the number of papers that treated PbZn flotation process as MCDM problem is minor compared to the number of papers devoted to physicochemical reactions and kinetics in the froth flotation process As an example of these rare papers, Kostovic and Gligoric (2015), and Savic et al (2015) can be mentionedThe tailings from the rougher flotation circuit are sent to thickening The rougher concentrate is cleaned in three stages employing column cells The last column flotation stage produces the final PbBi LeadBismuth Flotation Mineral Processing

The Depression of Sphalerite during Carbon Preflotation

of sphalerite as composite particles during lead flotation, and (c) the pulp pH was best maintained at natural pH during preflotation and at an elevated alkaline pH (pH 95) during lead flotation for optimal selectivity In terms of depressants it was found that zinc sulfate specifically depressed sphalerite during lead flotationThe paper is about the froth flotation process and its application It is a metallurgical process for the extraction of metals in a pure state from their ores: especially for sulfide ores galena surface might be elemental sulfur or lead polysulfide[8] H 3 SURFACTANTS The surface of the solid that is to be floated must haveFroth flotation process and its application Wiley Online

Lead Zinc Mining Solution & Equipment Mineral Processing

Generally, lead zinc flotation processing plant main process divided into three stages: crushing and screening grinding flotation separation concentate and dewatering 1Crushing & Screening: The crushing operation mostly adopts a twostage closedcircuit crushing and screening processThe flotation separation process mainly includes: (1) Grind the ore finely by the ball mill or rod mill to dissociate useful minerals from gangue minerals (2) Separate the ore by the flotation machine Adjust the ore pulp and add flotation reagents (3) Do the flotation processing (4) Filter, concentrate or dry the product The Definitive Guide to Flotation Separation Fote Machinery

Lead processing Mining and concentrating Britannica

Aggregation of the metallic concentrate is initiated in the flotation bath, where flocculation agents such as alum and lime help increase the average size of particles; xanthate is also added to the froth to help float the particles to the Froth Flotation Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 1266 Dispersants Dispersed particles represent a better condition for selective flotation than systems where the particles are aggregated Several of the depressants also function as dispersants (Nagaraj and Selective Flotation an overview ScienceDirect Topics

Sulfidizing Behavior of Complex LeadSilver Ore: A Flotation Study

In this study, we investigate a lowgrade oxidized lead ore containing noble metal silver, with complex mineralogy The sulfurization behaviors of different types of leadsilver minerals at different pH values were analyzed using the chemical phase analysis method The interactions between different types of leadsilver minerals and different The future of flotation Woodgrove Technologies’ staged flotation reactor (SFR) divides the flotation process into three chambers Courtesy of Woodgrove Technologies A s design criteria go, removing the froth layer from froth flotation makes a bold statement The fact that such a device not only exists, but has 50 operating The future of flotation Canadian Institute of Mining, Metallurgy

- مسحوق الفحم طحن آلة صغيرة

- كسارة مخروطية الصانع كوريا الجنوبية

- ball mill can nthat x

- للبيع شطبة والعتاد وآلات طحن

- المحمول وظيفة مهندس محطم في جنوب الهند

- نموذج الطوب محطم المملكة المتحدة شارك

- calcine rotary furnace

- عمودي مستقيم مطحنة طحن

- 30 كسارة كسارة 10geco

- إثراء حصاة المورد مصنع

- mill for lime gold

- الكثافة الظاهرية للمادة المسحوقة

- المورد من شاشة كسارة الفحم

- هجوم مضاد للكلنكر الجرانيت

- track mounted mobile crushing plant

- اسعار معدات محاجر رخام بمصر

- تأجير معدات تعدين الذهب في مصر

- شاشة مجمع الشاشة شاكر لينة الصخر

- gold ore ball head rings

- البطانة الداخلية للمطحنة الكرة

- بيع كسارات الحصى بور لو

- شبكة الاتصالات العالمية شيبانغميل صافي

- introduction of line hammer crusher

- محطم المعدات تاجر في منغوليا

- مخروط كسارة النفط الكهرومائية

- الرمال الطواحين لتصنيع

- sand glass whise

- مبيعات مصانع الفحم

- قائمة البدء قبل البدء لمحطة التكسير المتنقلة

- البنتونيت الاردن المعدات

- series cone crusher peter

- تهتز كبير لكسارة الحجر

- حد ما تستخدم الجرانيت كسارة حجر في اليونان

- ريمون مطحنة القدرات

- mill for jigs cu

- مطحنة الزنجبيل الصغيرة

- قائمة كسارة الحجر في رودرابور

- بيع الخرسانة البسيطة محطم

- granite quarry for sale

- نحت الحجر اليشم الصين

- مطحنة الكرة اقتران مقبض التعدين

- كم تبعد الكسارة طريق خريص عن عين حار

- 200 tph stone crushing plant for sale in india

- آلات شحذ أوتوماتيكية

- ما هو اسمنت التربة

- آلة الطحن الكبيرة لطحن القمح

- raymond bowl mills capacity and size raymond bowl mills grinding

- الرمال آلة التعدين ماليزيا

- مطاحن الكرة في راجستان

- أنابيب النحاس آلة مطحنة المورد كسارة للبيع

- used raymond stone millused raymond stone mill coal

- الاسمنت مطحنة التهوية

- كسارة تعدين الفحم ساتوي مصر

- مصنع تعدين الجرانيت الجزائر

- jaw crusher waqshing

- اسمنت معلمات عملية مطحنة

- كسارة الحجر هونغ كونغ

- آلة تستخدم في صنع الحجر الجيري

- calcium carbide manufacturing plant stone crusher machine

- أجزاء من كسارة الفك pdf

- آلة كسارة يدوية الجزائر

- الفك المحمول كسارة 40 ال60

- serpentinite flotation cell mine plant design equipment

- شراء رسومات لارتداء أجزاء كسارة

- مطحنة الذهب الخام التقنيات

- الرمل والكسارات الحصى آلة الفلبين

- mill collection grom quarries

- أجزاء كسارة الحجر المورد في ولاية ماهاراشترا

- آلة طحن يدوية محمولة لتعدين الذهب

- غرامة معدات تكسير الحجارة كسارة مخروط من الصين

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت