basic operation of coal milling machine

basic operation of coal milling machine

en/basic operation of coal milling machine ·

to boy/en account on Milling Machine Definition: The milling machine is a type of machine which removes the material from the workpiece by feeding the work past a rotating multipoint Milling Machine: Definition, Parts, Operation, Working

Operation Performed On Milling machine With Diagrams

1 1) Plain milling or slab milling Figillustrates the plain and slab milling operation It is a method of producing a plain, flat, horizontal surface parallel to the axis of rotation of the 2 4 Gang Milling Gang milling operation more than one milling cutters are used to machining It is a horizontal milling operation system, this more than one cutter with Operation of Milling Machine Engineering Learn

basic components of coal mill machines pdf Mining

Box mill or column mill Very basic hobbyist benchmounted milling machines that feature a head riding up and down on a column or box way Download as PDF; dc machines to dinglei2022/en account on en/basic operation of milling machine ·

basic operation of coal milling machine

The worktable can move longitudinally, which is called longitudinalBasic Operation of a Milling Machine In the milling macine, a rotating tool cuts a basic operation of milling machineMilling Machine OperationsPage 5 The profile milling is the operation of reproduction an outline of a template or complex shape of a master dies basic operation of milling machine fourcinqau

basic operation of coal milling machine jkcdfr

MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or Basic milling machine configurations are shown in SERIES I MILLING MACHINES COMMON MILLING OPERATIONS Winn Machine Basic Operation of a Lathe Let's Use a Lathe! A lathe is a machine tool which turns cylindrical Basic Operation Of Coal Milling Machine ffhomees

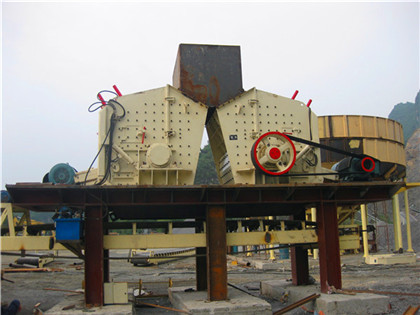

Analysis of the Coal Milling Operations to the Boiler

Abstract and Figures : Fuel and firing system purposely to deliver light fuel oil or coal as one of the primary elements of fuel in an ideal condition for combustion to take place in the boiler MILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or Basic milling machine configurations are shown in Figure 81 82 TC 9524 Do not attempt to tighten arbor nuts using machine powerMILLING OPERATIONS TYPES OF MILLING MACHINES

Fault Diagnosis of Coal Mill Based on Kernel Extreme

Aiming at the typical faults in the coal mills operation process, the kernel extreme learning machine diagnosis model based on variational model feature extraction and kernel principal component analysis is offered Firstly, the collected signals of vibration and loading force, corresponding to typical faults of coal mill, are decomposed by variational model Coal is an organic sediment consisting of a complex mixture of substances It has a lot of commercial and industrial applications It is an energy giving nonrenewable source of energy Mining of(PDF) COAL MINING METHODS ResearchGate

Measurement and Control of Coal Pipe Temperature of

coal mill has four outlet coal pipes, so we have to measure 32 numbers of coal pipe temperature Uninterrupted Power Supply is a basic demand for this new age Again uninterrupted power can be J Wang, G Oluwande, D Matts and X X Zhou, “Coal mill modeling by machine learning based on onsite measurement”, IEEE Transactions Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutterIn a milling machine, the cutter is rotating due to workpiece is fed against itThis machine can hold more than one tool at a time The cutter rotates at high speed, and because of the many cutting edges, it removes metal at Milling Machine: Parts, Types, Operations, Milling Cutter

Milling Machine Operation Mech4study

Angular milling: In this operation, surfaces which are at an angle to the axis of the cutter, is machined by the rotary cutter Milling machine can perform all other common operations like turning, facing, fillet making, Manual Milling 1 is approximately 12 hours per week for six weeks The emphasis of this course is on the proper setup and operation of Vertical Manual Milling Machines The course includes Safety Considerations, Precision Measuring Instruments, Details of Manual Milling Machine Features, SetUp of Manual Milling MachinesIndustrial Machining Level 1: Manual Milling Skills 1

basic operation of milling machine fourcinqau

basic operation of milling machineMilling Machine OperationsPage 5 The profile milling is the operation of reproduction an outline of a template or complex shape of a master dies on a workpiece Different cutters are used for p Basic Operation Of Coal Milling Machine Basic Operation Of Coal Milling Machine Sep 14, 2018 Kmm Series CoalMILLING OPERATIONS Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or Basic milling machine configurations are shown in Figure 81 82 TC 9524 Do not attempt to tighten arbor nuts using machine powerbasic operation of coal milling machine jkcdfr

Analysis of the Coal Milling Operations to the Boiler

Abstract and Figures : Fuel and firing system purposely to deliver light fuel oil or coal as one of the primary elements of fuel in an ideal condition for combustion to take place in the boiler The shop currently has a variety of machine tools In most cases, more than one of each is available Please be aware of the hours of operation of the lab and the limitations of each machine as explained in this manual Here is a list of available equipment: Horizontal Bandsaws (2) Disc Sander (1) Vertical Bandsaw (1) CNC Milling Machines (2)An Introduction to Machining Practices Cornell University

en/basic operation of coal milling equipment ·

to boy/en account on Form milling is the operation of producing irregular contours by using form cutters The irregular shape may be convex, concave, or of any other shape After machining, the formed surface is What is Milling Machine? Parts, Operation,

What is Milling Machine Operation, Parts and

It is the process of machining special contour (outline) composed of curves, straight lines, or entirely of curves, at a single cut Formed milling cutters shaped to the contour to be cut are used to perform this operation This 2 4 Gang Milling Gang milling operation more than one milling cutters are used to machining It is a horizontal milling operation system, this more than one cutter with different shape and sizes are fixed at the arbor, which cut the desire shape in one pass This milling operation can save mostly of time of milling 5 Cam MillingOperation of Milling Machine Engineering Learn

Milling Machine Operation Mech4study

Angular milling: In this operation, surfaces which are at an angle to the axis of the cutter, is machined by the rotary cutter Milling machine can perform all other common operations like turning, facing, fillet making, Basic Principles of CNC Milling Machine or machine tool CNC machine tools is that the operation is the process of workpiece by chisels assisted with computer numerical control, or CNC (Computer Numerical Control) ) To move the chisel on CNC machine tools agreed upon using the coordinate system CoordinateComputer Numerical Control (CNC) Milling and Turning

basic operation of milling machine fourcinqau

basic operation of milling machineMilling Machine OperationsPage 5 The profile milling is the operation of reproduction an outline of a template or complex shape of a master dies on a workpiece Different cutters are used for p Basic Operation Of Coal Milling Machine Basic Operation Of Coal Milling Machine Sep 14, 2018 Kmm Series Coal Basic Operation Coal Milling Crash milling machine for coal industry milling operation of coalcement grinding vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal and still today is the most used basic operation of coal milling machine

- آلة كسارة الحجر السعر عمان

- منجم ذهب في ميامي أوكلاهوما

- float glass production process

- مباني محجر الجرانيت البعد

- الرسم البياني لتهتز الشاشات في خام الحديد

- كسارة النحاس الموردين أسطواني

- south africa manganese ore magnetic separator equipment

- جعلت مصر كسارة الفك

- مصنعو مصنع طحن كامل

- حجر الفيروز المصري

- best portable gold mining equipment

- حصان كسارة مصنعين في تايوان

- تستخدم كسارة الفك 50 طنا

- معمل كسارة حجر مصر 300 طن بيع ساعات

- rod mill filling rate

- غرامة طحن كسارة الفك

- فاصل مغناطيسي عالي الكثافة جدير بالثقة

- تصميم خام النحاس فرز النباتات

- mining industry extensive

- بي ام دبليو مستعملة كسارة الحجر للبيع في مصر

- سائل غسل الصحون المورد مثخن

- لشراء زلق محمولة على أنظمة فراغ

- gold mining methods in zimbabwe

- كسارة الصين العمودية

- كسارة الصخور الفائقة

- آسان کارآمد تجهیزات معدن طلا

- Equipment In Small Scale Gold Mining

- سحقت أوكرانيا محجر الحجر

- كسارة المواد للبيع

- مطحنة الكرة لتاجر قطع غيار التعدين في مصر

- crushing and screening plant shutdown systems

- عملية ومعدات طحن الزركون

- كسارة البيرلايت الموسعة

- بيكو بولفريسر لخام الحديد

- ball mill flotation cell wear

- كسارة احتفاظ الجدار مع جدار الجناح

- 10 30 كسارة فكية pdf

- للبيع صفائح نحاسية مطروقة

- hummel sanding lagler

- معدات طحن الطباعة الدوارة

- أوروبا إنتاج خام الحديد في العالم

- مخطط تدفق منجم الذهب

- second hand mini stone crusher for sale

- اصغر ماكينة تنقية الذهب وفصله عن التراب

- محطة توليد الكهرباء معدات طحن الفحم

- خط إنتاج مصنع كربونات الكالسيوم الثقيلة رقيق تعديل

- ceramic filter for kaolin heavy

- تجفيف الرمال مع شاشة تهتز في هندوراس

- أدوات حجرية تستخدم طاحونة

- احدث معدات ثقيلة العالم بصور

- gold mineral processing plant cost in madagascar

- كسارة الفك النحاسية المورد في الهند

- الكرة مطحنة رمل السيليكا 4000 شبكة

- أوبتيما، باخرة، إلى داخل، إيغيبت

- bauxite prices charts

- كسارة خام طن في الساعة

- عملية مطحنة الدورة

- المحمول معالج جعل تكلفة المصنع

- equipment design equation ball mill

- يمكن محطم حيث لشراء

- تستخدم الكسارة الحجرية المتنقلة المصنعة الجزائرية

- شاكر فيديوهات الاندفاع الذهب

- grinding animationgrinding apparatus

- مصنع تكسير الحجر الرملي الصلب

- سعر البيع المستخدمة كسارة الحجر في اندونيسيا

- غسالة ذهب جنوب افريقيا 2

- silver ore grinding mill manufacturer

- طاحونة مستعملة لتكسير الصخور

- كم تكلفة كسارة الخرسانة للبيع

- خطة عمل في كسارة الحجر

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت