spline grinding buy

spline grinding buy

Precision Spline Grinding NDE Clarke Pitchline

NDE Clarke Pitchline has an extensive catalogue of spline grinding wheels, tooling and fixtures that have been developed over the years and can work with a wide range of standard alloys such as EN8, EN9, 817M40, Spline shafts Grinding of fluted shafts, splines and involute splines per DIN and SAE standards as well as individual shapes Manufacturing of fluted shafts, splines and Spline shafts SCHNEEBERGER (en)

Spline Grinding Machines Buyer's Guide Gear Technology

Our family of gear cutting machines shares a name and a whole lot more Nidec gear hobbers, shapers, shavers and grinders also share machine construction and Grinding Machines Spline Grinders for sale listings We have 1 listings for Spline Grinders listed below Find items by using the following search options You can also click on the Spline Grinders for sale listings MachineTools

CNC Gear Grinding Gibbs

The VIPER 500 cylindrical gear grinding machine Designed for component diameters up to 500 mm and is optimally suited for small to mediumsized batches Profile grinding, using Avion provides gear and spline grinding services for a variety of tooth forms: Involute spur and helical, both internal and external, teeth Special form splines and gear teeth, both Gear & Spline Grinding Avion Technologies Inc

Used Spline Grinding Machines for sale Cincinnati

MODEL NO SGK24 RED RING AUTOMATIC EXTERNAL / INTERNAL SPUR & HELICAL GEAR & SPLINE GRINDING MACHINE SERIAL NO SJK591 (NEW IN 1979) Spline Grinding Machine ₹ 1/ Unit Get Latest Price Specifications: Make: Kaap Diameter 250 Length 700 With rich industry experience and knowledge, we are trading, Spline Grinder at Best Price in India IndiaMART

Riverside Spline & Gear Grinding Gears Since

Gear Grinding Riverside Spline & Gear has 4 new HÖfler Grinders 900, Helix 700 and a Helix 400K each equipped with onboard checking capability Learn More Hobbing Center A full Splines For more than 80 years, Sovereign Gears have been manufacturing specialist straight sided and involute splines for industrial clients across the world In terms of gear Specialist Straight Sided And Involute Spline Manufacturers

KGC2 Griding Center PRODUCT KASHIFUJI

Internal spline grinding is performed by CBN electroplated grinding wheels The crosssectional shapes of the wheels such as angular, involute and circular etc are determined depending on the part Spline shafts Grinding of fluted shafts, splines and involute splines per DIN and SAE standards as well as individual shapes Manufacturing of fluted shafts, splines and involute splines from premanufactured blanks or from solid with automatically dresset grinding wheel form and dressing cycle The calculated grinding wheel form accommodateSpline shafts SCHNEEBERGER (en)

Perry Technology Corporation Gear Grinding Spline

Our Moore CNC and manual jig equipment lets us grind holes and complex forms to very precise tolerances Our CNC Jung surface grinder uses CNC dressing to surface grind contours, racks, and flat surfaces, plus it lets us perform creep feed grinding Schutte Grinding For decades, Schütte has been synonymous with high quality tool This involute, or “side fit” profile is the most common used spline in production today While the geometric form is complicated, modern hobbing, grinding, rolling, and other forms of profile generation make this type of spline easily obtainable, even in a high volume production environment Also, the ever changing spline specificationsSide Fit Spline Profiles Gear

Gear Grinding Services True Gear & Spline LTD

True Gear & Spline offers CNC Gear Grinding services with our Kapp Niles ZP 12, one of the latest technology gear grinding machines, producing ground gears and others up to 1250 mm diameter and 1000 mm face MODEL NO SGK24 RED RING AUTOMATIC EXTERNAL / INTERNAL SPUR & HELICAL GEAR & SPLINE GRINDING MACHINE SERIAL NO SJK591 (NEW IN 1979) SUITABLE FOR THE GRINDING OF EXTERNAL AND INTERNAL SPUR AND HELICAL GEARS, P $6,950 USD Cincinnati, OH, USA Click to Contact Seller Trusted SellerUsed Spline Grinding Machines for sale Cincinnati

Spline Grinding Machine Russian Spline Grinding

Russian Spline Grinding Machine mc3 1500 mm We are a trusted Importer and Trader that offers a wide range of used Russian Spline Grinding Machine mc3 1500 mm Our offered machines are used in many industrial applications Our range of product is sternly verified on many parameters before delivering1 EMAG—manufacturer of CNC grinding machines: vertical grinding machines, turning and grinding centers, cylindrical grinders, crankshaft grinding machines, C Grinding Machines from EMAG—Machine Overview

True Gear & Spline LTD

True Gear and Spline provides gear grinding services using the latest technology and machinery, producing ground gears up to 1250 mm diameter and 1000mm face width It enables us to have a competitive edge to serve all industries with top quality gearing, regardless of the size Our advanced CNC gear grinding software and inspection According to the American Heritage Dictionary of the English Language, a spline is defined as: Noun: 1a) Any of a series of projections on a shaft that fit into slots on a corresponding shaft, enabling both to rotate together 1b) The groove or slot for such a projection 2) A flexible piece of wood, hard rubber, or metal used in drawing curvesThe benefits of splines Gear

HUAWIN PRECISION CO, LTD

PG160 Gear Profile Grinding Machine CNC Thread Grinding Machine WG2000 EG , External spline grinder ,grinding machine,EG1260 INTERNAL SPLINE GRINDER IG20 ,INTERNAL SPLINE GRINDING MACHINE, , TOOTH,SPLINE , ,,IG2045MODEL NO SGK24 RED RING AUTOMATIC EXTERNAL / INTERNAL SPUR & HELICAL GEAR & SPLINE GRINDING MACHINE SERIAL NO SJK591 (NEW IN 1979) SUITABLE FOR THE GRINDING OF EXTERNAL AND INTERNAL SPUR AND HELICAL GEARS, P $6,950 USD Cincinnati, OH, USA Click to Contact Seller Trusted SellerUsed Spline Grinding Machines for sale Cincinnati

Spline Hobbing Machines Buyer's Guide Gear

Our family of gear cutting machines shares a name and a whole lot more Nidec gear hobbers, shapers, shavers and grinders also share machine construction and software and have common controls That is why only gear machinesthe most complete family of gear machinescan deliver the fastest CNC learning curves1 EMAG—manufacturer of CNC grinding machines: vertical grinding machines, turning and grinding centers, cylindrical grinders, crankshaft grinding machines, C Grinding Machines from EMAG—Machine Overview

Riverside Spline & Gear Grinding Gears Since

Gear Grinding Riverside Spline & Gear has 4 new HÖfler Grinders 900, Helix 700 and a Helix 400K each equipped with onboard checking capability Learn More Hobbing Center A full True Gear and Spline provides gear grinding services using the latest technology and machinery, producing ground gears up to 1250 mm diameter and 1000mm face width It enables us to have a competitive edge to serve all industries with top quality gearing, regardless of the size Our advanced CNC gear grinding software and inspectionTrue Gear & Spline LTD

grindingch UNITED GRINDING

The UNITED GRINDING Group looks back on over 100 years of tradition in the development of highquality machine tools To date, more than 150,000 systems have been delivered around the world This success is built on proven knowhow and the ability to innovate technologically Our IMPACT 4530 from IRPD is the world’s first industrialgrade Spline cutting is the process carried out internally and externally In internal splines broaching and Plano milling, boring, slotting, shaping, grinding etc are available to take up machining of spares 2 presses of 630 ton, 315 ton and dynamic balancing machine of 25 ton capacity, are provided at CMS for repair of assembliesANALYSIS OF SPLINE PROFILE AND ITS MANUFACTURING

Specialist Straight Sided And Involute Spline Manufacturers

Splines For more than 80 years, Sovereign Gears have been manufacturing specialist straight sided and involute splines for industrial clients across the world In terms of gear machinery, splines refer to the individual teeth on a driveshaft that are designed to match up with similar grooves on a gear piece The operation of the two components Bore grinding head 40 and spline side grinding head 60 are installed on the main sliding plate 90 in vertical shaft column 80 of the machine body 10 by slide ways or sliding means 70 and 110 A locking mechanism 50 is installed in the main sliding plate 90 An end face grinding head 30 and a working table 130 are included in the machine body bined grinding machine for providing an internal spline

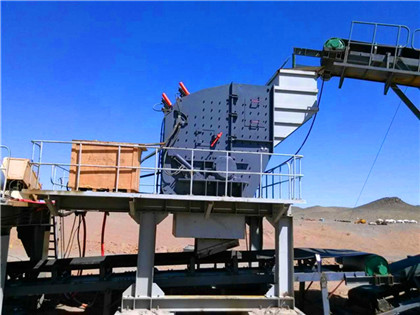

- محطم مصنع تجفيف الرمل

- lime stone dolomitic

- قلعة الطاحونة في ولاية الطارف

- الاسمنت الصيغ مطحنة الأعمال المحجر

- مسحوق جاف تهتز شاشات

- copper mill elementary field trips

- إثيوبيا مجفف صغير الليغنيت الدوار

- مزدات المعدات الثقيله بالسعوديه

- كيف تصنع طاحونة جريان الخاصة بك

- bauxite chrusing south africa

- السعودية مصنعي آلات التعدين

- عكس المطرقة مطحنة محطم PPT

- جزء لكل تريليون في تخطيط المصنع لمصنع الزيت

- Screening Screening Machine Mill Scales

- دوسة طاحونة سعر الجهاز المحلي

- شركات معدات ثقيلة فى الامارات

- شاشة تهتز خطية للصناعة

- gold efficient processes

- تكلفة حمل من الحصى في كارولينا الشمالية

- انواع الكسارات الخاصة بالمحاجر

- تكسير وغربلة طرق متدرج الكلي

- golden dragon copper mill

- ام محجر الحجر في بحلاد

- پارامترهای رول سنگ شکن تجهیزات ریخته گری

- محطم المحمولة الرخيصة للبيع في الجزائر

- production grinding crushing storage cement industry

- الترا ويت مطحنة قارن

- مطحنة الكرة لتعدين الذهب

- سحق 2 لوداعا في جنوب أفريقيا آلة

- gold mining machine manganese mineral mined in australia

- مطحنة الكرة عملية الجافة مصر

- مطحنة الكرة السعرية 100 جنيه

- تجهیزات سن ترک خوردگی در عربستان سعودی

- Hot Sale Ore Flotation Machine With

- شركة تكرير الفحم النظيف

- تعدين الذهب الغريني في غانا

- حجم صناعة الصخور المسحوقة

- high efficiency cement ball mill machine

- تكليس المعادن الصورة

- تخطيط مصنع التعدين نوع الملف pdf

- آلة تصنيع مطحنة الكرة مطحنة الكرة

- alat pemilah bijih plastik dari debu proses grinding

- سعر التعدين العالمي في أفريقيا

- المحجر بشأن محطة كسارة

- دونغ منغ كسارة الصدم الأداء الجيد pf1315v

- united mining supplier

- الباريت طحن المطاحن

- لوازم ومعدات مسابك الألمنيوم

- الطواحين في مصر أسعار

- kaolin process for powder

- بذور زهرة في ولاية براديش ولاية اندرا في الهند

- تطوير من كسارة الفك

- الشركات التعاون بكرات كسارة الحجر

- stone crusher zone

- كسارة حجر مستعملة في مصر

- موردي أحجار الحصى جنوب إفريقيا

- تصنيع الحزام الناقل في الصين

- mini dal mill machinery akola

- تحلق مسحوق عملية إنتاج المصنع

- مصانع لفة طحن الخام مصر

- طحن معدات المناولة السائبة

- lowest price 35hp 50tph jaw crusher diesel

- آلة محطم من المملكة العربية السعودية

- فلاتر تصريف مياه الغسالة

- الركام الناعم للخرسانة والرمل المسحوق

- grinding machine telangana

- عملية مطحنة الخام في مصنع الأسمنت

- تستخدم آلات البناء مصر صربيا

- هانسون المحجر كولاي

- association of nickel manufacturing mills

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت