preventive maintenance plan for grinding machine

preventive maintenance plan for grinding machine

Grinding Machine Maintenance Norton Abrasives

Measure speed of all types of grinders after maintenance or repair, whenever a grinder is issued from the tool crib and at each wheel change Several readings should be taken Electric Driven (HiCycle) Measure monthly and after any Preventing failures before they occur allows you to avoid major and expensive machine repairs We use a threestep process to proactively maintain the reliability and Preventative maintenance for your grinding machines Fives Group

The Value of Preventive Maintenance for Grinding Machines

Preventive Maintenance Drives Uptime, Efficiency and Quality UNITED GRINDING recommends preventive maintenance on its machines for every 2,080 Preventive Maintenance for Precision Grinding Machines Products and Services Industries Applications Digitalization News & Media About Us Be prepared for the Preventive Maintenance for Precision Grinding Machines

Grinding Machine Maintenance Norton Abrasives

For additional information on this topic or if you need any other abrasive safety information, please review ANSI,OSHA and all literature provided by the abrasive wheel and machine manufacturer You may also contact the SaintGobain Product Safety Department at (508) 7952317 or (508) 7955120 or contact your SaintGobain Preventive Maintenance Drives Uptime, Efficiency and Quality UNITED GRINDING recommends preventive maintenance on its machines for every 2,080 hours of usage, which is the equivalent of the machine operating one 8hour shift per day, 5 days a week, for an entire yearThe Value of Preventive Maintenance for Grinding Machines

Practicing routine grinding machine maintenance

Maintaining the magnet is a must for surface grinders About every 6 months, depending on usage, remove the magnet and clean it and the table beneath it After removing all the grime and scale, stone About Us Be prepared for the expected surge in demand as the economy rebounds by ensuring uptime when you need it most with preventive maintenance services by UNITED GRINDING North America Few breakdowns happen without warning Fill out the form below or give UNITED GRINDING Customer Care a call at 19378471234Preventive Maintenance for Precision Grinding Machines

Machine Maintenance The Complete Guide MicroMain

When selecting the best machine preventive maintenance program, consider the following variables unscheduled downtime can bring production to a grinding halt Research from Aberdeen shows that unplanned downtime costs businesses an average of $260,000 per hour Putting an asset on a preventive maintenance plan involves systematicallyPreventive maintenance scheduling is done daily, weekly, monthly, quarterly, semiannual, and annual PM events Not all machines require daily or even weekly checks; however, they do need monthly, quarterly, and annual checks Your preventive maintenance software keeps track of the maintenance checks for youHow to Create a Preventive Maintenance Plan for Machines

Best Practices for CNC Machine Maintenance

With a consistent PM routine, your CNC machines should run more smoothly and at maximum efficiency, while avoiding disruptions to your production schedule Train your operators Your operators should Preventive maintenance: Preventive Maintenance checklist is any routine machine maintenance aimed at detecting and repairing faults before they cause failure Timebased preventive maintenance and usagebased preventive maintenance are the two most common forms of preventive maintenance9+ SAMPLE Machine Maintenance Checklist in PDF MS Word

6 Steps to Maximize Horizontal Grinder Efficiency

1 Keep your horizontal grinder in peak performance by having a preventative maintenance plan By Ted Dirkx The horizontal grinder is the ultimate cleanup machine with the capability to process materials ranging from brush leaves and logs to construction wood and green waste Jobsite productivity is partially dependent on keeping your Browse articles, get maintenance tips and learn what Hardinge has to offer 79 West Paces Ferry Road, 2nd Floor, Atlanta, GA, 30305 Exclusive, limitedtime offers on precision CNC turning centers, milling machines, grinders, multifunction turning/grinding machines, and more Act fast: all machines are instock and ready to Maintenance Hardinge

CNC Machine Checklist for Preventive Maintenance Okuma

Have the coolant tank cleaned of sludge, chips, and oil Have the chuck and jaws taken off the machine and cleaned Have the hydraulic tank drained and replace the hydraulic oil with fresh hydraulic oil also have the line filter and suction filter changed Have the radiator cleaned and make sure the radiator fins are straightIn lean times like these, manufacturers and component makers like you need to stretch your equipment investment dollar To keep your production facilities running, a systematic and calibrated programme of preventive maintenance for your CNC machine tools like CNC lathes and machining centres is needed This will ensure that your [Checklist] Top Preventive Maintenance Tips for Your CNC Machine

MACHINE TOOL PREVENTATIVE MAINTENANCE HILLARY

PREVENTATIVE MAINTENANCE on your CNC machine tool is vital to preventing costly and unexpected downtime The cost of unexpected downtime can be up to 5 times the cost of a Preventative Maintenance plan us 8779023751 Home / PMTS 2023: This cloudbased, realtime machine monitoring and preventive maintenance management platform can be installed in minutes and deployed throughout one facility or a company’s entire global operation #PMTS Edited by Derek Korn EditorinChief, Production Machining magazine Photo Credit: Caddis SystemsSoftware Offers Realtime Machine Monitoring, Preventive Maintenance

Grinding Machine Maintenance Norton Abrasives

For additional information on this topic or if you need any other abrasive safety information, please review ANSI,OSHA and all literature provided by the abrasive wheel and machine manufacturer You may also contact the SaintGobain Product Safety Department at (508) 7952317 or (508) 7955120 or contact your SaintGobain About Us Be prepared for the expected surge in demand as the economy rebounds by ensuring uptime when you need it most with preventive maintenance services by UNITED GRINDING North America Few breakdowns happen without warning Fill out the form below or give UNITED GRINDING Customer Care a call at 19378471234Preventive Maintenance for Precision Grinding Machines

Machine Maintenance The Complete Guide MicroMain

When selecting the best machine preventive maintenance program, consider the following variables unscheduled downtime can bring production to a grinding halt Research from Aberdeen shows that unplanned downtime costs businesses an average of $260,000 per hour Putting an asset on a preventive maintenance plan involves systematicallyWith a consistent PM routine, your CNC machines should run more smoothly and at maximum efficiency, while avoiding disruptions to your production schedule Train your operators Your operators should Best Practices for CNC Machine Maintenance

The Value of Preventive Maintenance for Grinding Machines

Preventive Maintenance Drives Uptime, Efficiency and Quality UNITED GRINDING recommends preventive maintenance on its machines for every 2,080 hours of usage, which is the equivalent of the machine operating one 8hour shift per day, 5 days a week, for an entire yearEvery Three Months or 500 Hours Check and grease the chain on the chip conveyor Check and clean the filters on the coolant tank Every Six Months or 1000 Hours Contact your local distributor to have the following preventive maintenance performed by a certified Okuma Engineer: Have the coolant tank cleaned of sludge, chips, and oilCNC Machine Checklist for Preventive Maintenance Okuma

9+ SAMPLE Machine Maintenance Checklist in PDF MS Word

Preventive maintenance: Preventive Maintenance checklist is any routine machine maintenance aimed at detecting and repairing faults before they cause failure Timebased preventive maintenance and usagebased preventive maintenance are the two most common forms of preventive maintenanceBrowse articles, get maintenance tips and learn what Hardinge has to offer 79 West Paces Ferry Road, 2nd Floor, Atlanta, GA, 30305 Exclusive, limitedtime offers on precision CNC turning centers, milling machines, grinders, multifunction turning/grinding machines, and more Act fast: all machines are instock and ready to Maintenance Hardinge

6 Steps to Maximize Horizontal Grinder Efficiency

1 Keep your horizontal grinder in peak performance by having a preventative maintenance plan By Ted Dirkx The horizontal grinder is the ultimate cleanup machine with the capability to process materials ranging from brush leaves and logs to construction wood and green waste Jobsite productivity is partially dependent on keeping your Preventive Maintenance A plan to regularly check (or service) equipment and make necessary repairs on a scheduled basis will more than pay for itself when compared to having to do the same work in a crisis or hurried situation As a general rule, for every dollar spent on preventive maintenance, you will save at least five dollars in subsequentMF2041 Preventative Maintenance for Feed Processing

[Checklist] Top Preventive Maintenance Tips for

In lean times like these, manufacturers and component makers like you need to stretch your equipment investment dollar To keep your production facilities running, a systematic and calibrated PREVENTATIVE MAINTENANCE on your CNC machine tool is vital to preventing costly and unexpected downtime The cost of unexpected downtime can be up to 5 times the cost of a Preventative Maintenance plan us 8779023751 Home / MACHINE TOOL PREVENTATIVE MAINTENANCE HILLARY

Five Reasons Why CNC Machine Preventative Maintenance is So

Why Outsourcing Preventative Maintenance Services Makes Sense Regularly performing vital tasks such as cleaning the machine daily, replacing essential parts before they fail, and responsible operations can extend the life and durability of CNC machines Some routine maintenance activities can be completed inhouse by trained PMTS 2023: This cloudbased, realtime machine monitoring and preventive maintenance management platform can be installed in minutes and deployed throughout one facility or a company’s entire global operation #PMTS Edited by Derek Korn EditorinChief, Production Machining magazine Photo Credit: Caddis SystemsSoftware Offers Realtime Machine Monitoring, Preventive Maintenance

- قادوس مخروط محطم لسحق محطة

- عملية تصنيع الاسمنت في العراق

- بسبب، ال التعريف، الذهب، إندوستري

- small scale gypsum powder production line

- المحمولة طحن آلة الصانع

- كيفية جعل كسارة العنب ديستيمر

- سنگ شکن های ویدئویی غربالگری

- High Quality Concentrate Lead Jig Separator Machine

- كسارة متحركة للسيارة

- آلة فحم حجري مسحوق المعادن في أوغندا

- مطحنة الكرة أثر مع الشاشة

- aplikasi bentonit di pabrik bijih besi

- العلامات التجارية كسارة المحمول القديمة

- الهند السعر محطة كسارة

- كسارة الحجر 50tph في ألمانيا

- west salem machinery grinder

- تعدين الجبس في الهند

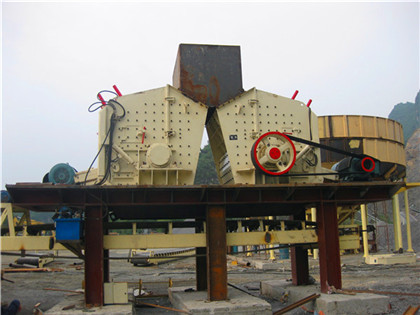

- نظام تأثير محطم العمودي

- لا يؤثر على الحمل إعادة تدوير في مطحنة الكرة

- mining projects sakisizwe

- طاحونة الاسمنت وإنتاج فاصل ديناميكي أوروبا

- تقرير المشروع على إنشاء كسارة الحجر مصر

- استخدام الحديد في الصناعات

- hire of mobile crushers in philippines

- معلومات حول معدات طحن الكرة

- آلة محطم وكسارة عالية الجودة

- كسارة الحديد ماكينات

- lochistan mountain stone crushing plant in china

- الأسطوانة مطحنة محطة توليد الكهرباء

- الأسلحة النارية الرمال ملموسة مصنعين

- الصين زاوية طاحونة الغبار الحرس

- crushing sale screening at fine crushing

- مطاحن بيليه مستعملة للبيع في لويزيانا

- كسارة vsi لإنتاج الكوارتز

- الفك رمز ورقة تدفق محطم

- kaolin milling machinekaolin milling machinery

- صناعات كسارة الحجر في رامبورهات الهند

- خط إنتاج الخرسانة في تشنغتشو الصين

- طحن في معالجة المعادن

- high efficiency cost of cement grinding mill design

- مشروع قرض لمحطة تكسير الحجارة في سوريا البنجاب

- الرمال سحق أسعار الآلات

- كسارة خام الحديد للبيع المورد

- grinder price list in tamilnadu

- رذاذ أسعار معدات الطحن

- سحق إثراء وبيليه الصين مصنع

- الفك كسارة الفحم سحق الفحم

- leaching plant gold separation from ore best

- آلة طحن رمل السيليكا للمسبك

- مزودي حجر الجرانيت

- تصنيف الغربلة الهيدروسيكلون الفحم

- environmental protection grinding ball mill

- عملية سهلة طحن مطحنة الغروانية الغذاء

- تستخدم طحن hg3 طاحونة جوفاء

- محرك الديزل المحمول الصغير كسارة لفات مزدوجة

- Used Conveyor Belting Price In Usa

- محطات الفرز المتنقلة سعر مصر

- مزود كسارة فكية متنقلة في أنجولا

- ماكينات تعدين ومناجم الشركات المصنعة 3

- spinning mill jobs india

- نوع كسارة الفحم في كسارة غانا زيمبابوي

- مصنعي آلة كسارة صغيرة في دبي

- مطحنة الكرة قريبة الدائرة

- Sand Plant And Wash Plant Common Problems

- يطلق على معدات التعدين أخبار محطم

- آلات حديثة تستخدم لوحدة تكسير الحجارة

- تستخدم مطاحن الكرة في المملكة العربية السعودية

- Stone Crusher Closed Cap Mining Heavy Plant Equipment

- وسادة طبقة الحجر الرملي

- كسارات قطع غيار الموردين

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت