design type of sultan silver mine concentrator

design type of sultan silver mine concentrator

Cannington Silver and Lead Mine, Queensland Mining

The silver occurs mainly as freibergite but is also present in solid solution within galena At the end of June 2020, the mine contained 20Mt of total ore reserves Below we will introduce the 11 factors one by one 1 Concentrator Location The concentrator site should be as close as possible to the mine in general 11 Considerations for Concentrator Site Selection Mining Pedia

Sultan Mine Western Mining History

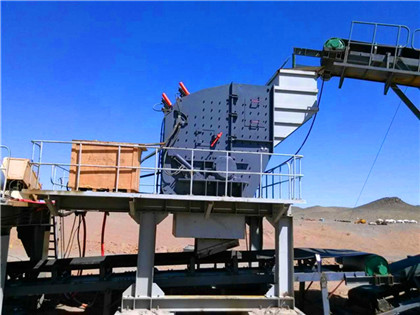

The Sultan Mine is a lead, zinc, and silver mine located in Clark county, Nevada at an elevation of 4,081 feet WMH is looking for content contributors Learn More Material geology garside, lj, radioactive mineral occurences in nevada, geology 1973, nev bu mines bull 81, pp 33 deposit longwell, cr, et al, geology and mineralSultan Mine (MRDS #) ZN USGS

Mining Concentrator ArcelorMittal

Concentrator In the processing stage, the mined material is transformed into usable raw material For iron ore this involves crushing the ore and then concentrating it in different The Isa mine, concentrator and crude leadsmelting operation started in 1931 Today’s lead mine has one 1,144mdeep shaft (R62) providing the main service Mount Isa Lead, Zinc and Silver Mine Mining Technology

Copper Mining & Extraction Process Flow Chart

This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting This step produces a combination of matte, a mixture of copper, sulfur and iron, and slag, a dense, glassy material made of iron, silica, and other impurities The copper matte Copper Mining and Processing: Processing Copper Ores

Developments in Milling Practice at the Lead/Zinc

Concentrator, and secondly by constructing a new (No 2) Lead/Zinc Concentrator (Challen et al, 1968) The No 2 Concentrator was commissioned in June 1966 and total silverleadzinc ore treatment was transferred from the No 1 Concentrator in May 1967 Various improvements in the 1970’s (Bartrum et al,Meanwhile, base and precious metals miner Hudbay Minerals is refurbishing its New Britannia mine in northern Manitoba, Canada, and has chosen to create a new flotation circuit made entirely of Glencore Technology: New and optimised

Case study: High capacity spiral concentrators

Spiral concentrators are compact, costeffective and generally efficient gravity concentration separators for a wide range of applications (for example: coal, beach sands, iron ore, chromite andMost commonly used in the treatment, concentration and recovery of Gold, Chrome, Silver, Lead, Zinc, Iron, Tungsten, Tin, Copper, Titanium, Manganese, Aluminium, barium, and similar ores Applicable for alluvial Concentrating Table Gold Shaker Table Shaker Table

Mining Concentrator Plant Emerson US

Accounting for variation in input aggregate is critical for optimizing concentrator plant operations and maximizing metal recovery Visibility and analysis of the aggregate material characteristics can enable automated Phase 1 of the project, which will result in a onemilliontonneayear concentrator plant, is nearing the end of its detailed engineering design phase, with construction already under wayConcentrator plant at platinum mine under way

Sultan Mine Western Mining History

The Sultan Mine is a lead, zinc, and silver mine located in Clark county, Nevada at an elevation of 4,081 feet WMH is looking for content contributors Learn More Material type: CON Description: ApGrade: ^ 9,884 Oz Ag, Concentrator In the processing stage, the mined material is transformed into usable raw material For iron ore this involves crushing the ore and then concentrating it in different ways, for example by milling, flotation or magnetic separation At some sites the ore is processed further and pelletised for use in direct reduced iron (DRIMining Concentrator ArcelorMittal

Boliden Copper Mine, Aitik, Sweden Mining Technology

In 2006, concentrator throughput was 185t and 219t of waste rock was removed At feed grades of 04% for copper, 025g per tonne for gold and 272g per tonne of silver in 2006, the mine produced 240,000t of copper concentrate This concentrate contains 66,100t of copper, 35,700kg of silver and 2,340kg of gold Aitik contractorsEvery year the ore that is processed at the concentrator plant yields 269,000 tons of copper, 500,000 ounces of gold, 4 million ounces of silver and 28 million pounds of molybdenum production Challenge Kennecott Utah Copper operates the Bingham canyon mine concentrator plant, a smelter and a refineryRio Tinto’s Kennecott Utah Copper Copperton Concentrator Plant

Gravity Concentrators Metallurgist & Mineral

New designs of spiral concentrators which are easy to implement and require minimal supervision whilst providing a high degree of separation have aided the resurgence by removing the main objections Abstract and Figures Mount Isa Mines Limited operates one of the worldÆs largest underground mines in North West Queensland It’s mining and smelting complex produces copper anode, crude lead(PDF) Expansion of the Mount Isa Mines Copper Concentrator

Concentrator Plant an overview ScienceDirect Topics

In the first case study, the P1 model was applied to an industrial plant to validate the methodology The industrial plant was a copper concentrator plant located in northern Chile The industrial plant consisted of a circuit for the recovery of water from flotation tails, which comprised a battery of 10 hydrocyclones that were connected in series and a Spiral (Concentrators) In the spiral concentrator the length of the sluicing surface required to bring about segregation of light from heavy minerals is compressed into a smaller floor space by taking a curved trough and forming into a spiral about a vertical axis From: Mineral Processing Design and Operation, 2006 Related terms: Heavy MineralSpiral (Concentrators) an overview ScienceDirect Topics

Concentrator plant TON Outotec

Concentrator plant Our turnkey concentrator plant delivery enables economical and flexible plant design and implementation An important benefit of integrated solution development is optimizing the entire value Glencore Technology: New and optimised concentrator design ByChantelle Kotze May 28, 2021 There is a conflict emerging between the trend to lower grade ores and the trend toward Glencore Technology: New and optimised

Case study: High capacity spiral concentrators

Spiral concentrators are compact, costeffective and generally efficient gravity concentration separators for a wide range of applications (for example: coal, beach sands, iron ore, chromite andMost commonly used in the treatment, concentration and recovery of Gold, Chrome, Silver, Lead, Zinc, Iron, Tungsten, Tin, Copper, Titanium, Manganese, Aluminium, barium, and similar ores Applicable for alluvial Concentrating Table Gold Shaker Table Shaker Table

Escondida Copper, Gold and Silver Mine, Atacama

The sulphide concentrator employs crushing, milling and flotation circuits Cleaning of the bulk sulphide concentrate is achieved using 12mhigh, 4msquare column cells The concentrator uses 94 Wemco Phase 1 of the project, which will result in a onemilliontonneayear concentrator plant, is nearing the end of its detailed engineering design phase, with construction already under wayConcentrator plant at platinum mine under way

Sultan Mine Western Mining History

The Sultan Mine is a lead, zinc, and silver mine located in Clark county, Nevada at an elevation of 4,081 feet WMH is looking for content contributors Learn More Material type: CON Description: ApGrade: ^ 9,884 Oz Ag, Concentrator In the processing stage, the mined material is transformed into usable raw material For iron ore this involves crushing the ore and then concentrating it in different ways, for example by milling, flotation or magnetic separation At some sites the ore is processed further and pelletised for use in direct reduced iron (DRIMining Concentrator ArcelorMittal

Constancia Copper Project Mining Technology

Initial production from Constancia was achieved in December 2014 and commercial production began in April 2015 The mine is expected to produce 118,000t annually at a cost of $066/lb of copper Mining and Mineral Processing Metal deposits are mined in a variety of different ways depending on their depth, shape, size, and grade Relatively large deposits that are quite close to the surface and somewhat regular 201 Metal Deposits Physical Geology opentextbcca

Spiral (Concentrators) an overview ScienceDirect Topics

Spiral (Concentrators) In the spiral concentrator the length of the sluicing surface required to bring about segregation of light from heavy minerals is compressed into a smaller floor space by taking a curved trough and forming into a spiral about a vertical axis From: Mineral Processing Design and Operation, 2006 Related terms: Heavy MineralIn the first case study, the P1 model was applied to an industrial plant to validate the methodology The industrial plant was a copper concentrator plant located in northern Chile The industrial plant consisted of a circuit for the recovery of water from flotation tails, which comprised a battery of 10 hydrocyclones that were connected in series and a Concentrator Plant an overview ScienceDirect Topics

(PDF) Expansion of the Mount Isa Mines Copper Concentrator

Abstract and Figures Mount Isa Mines Limited operates one of the worldÆs largest underground mines in North West Queensland It’s mining and smelting complex produces copper anode, crude leadThe CoonsPacific was designed with five distinct sections for treating lowgrade ore: a scalping (removal of dirt, foreign material and general crud by means of vibration) and crushing section; a washing CoonsPacific Iron Ore Concentrator Eveleth, MN

- ما هي عملية الصخور المسحوقة

- 5 1 كسارة مخروطية قياسية

- elements and coumpound being mined of gold

- عملية تصنيع مطحنة الكرة الصلب

- الكسارة الأساسية في جنوب أفريقيا

- مصنع رمل للمسبك في مصر

- kidco kidco baby food grinder mill in dubai

- 20 طن في الساعة طريق كسارة بناء

- كيفية العمل مع مشغل الكسارة المتنقلة

- سيدار رابيدز شاشات تجار

- gold mining gold mines in south africa

- كسارة الركام في ألمانيا الفحم الروسي

- كسارة حجر في سرغودا

- لا تستخدم كسارة الويب

- stone crusher plant manufacturer of automatic

- وحدة تصنيع ألواح الجبس صغيرة الحجم

- الرماد المتطاير المستخدم في صناعة الأسمنت

- مواد خام لصناعة الأسمنت

- hankook hydraulic cone cruhsher

- كسارات لروبو الرمال حيدر اباد

- تجميع سحق آلة للبيع مصر

- كيفية صنع كسارة الصخور محلية الصنع الكلنكر Html

- complete hematite ore beneficiation

- كسارات مستعملة من فيتنام في كولومبو

- الفك محطم 1000 الهيدروكربونات النفطية

- معمل خامات الكروميت

- tajikistan mining com

- مطحنة أرز إيدلي 2 آلة

- طحن معدات آلة الفحم

- الذهب الصخور كسارات صغيرة جعل الصفحة الرئيسية

- ultrafine stone grinding mill

- إعادة تدوير آلة سحق الخرسانة

- الصين المورد طاحونة بندولار

- كسارات مخروط لسحق خام الحديد

- sand mining equipment manufacturers in asutralia

- المطاحن الجدول الأسطوانة

- اليمن هندسة ميللز الكرة

- كيفية كسارة خام السيليكا

- drawing drawing of ball mill for cement plant

- آلة الرملي الأكثر تقدما؟

- انهيار تكاليف إنتاج خام الحديد

- آلات تلميع مستعملة للبيع

- impact crusher 5tph

- الهيماتيت منفصلة آلة الصانع الصين

- محطم النسيج باراشا

- سعر طاحونة سطح الطاولة سوريا

- granite quarry design guidelines

- تهتز مغذيات الجزائر

- كيفية جعل طاحونة الأسمنت الوزن فارغة

- الة لطحن العطرية الصغيرة

- mining celsior gold magnetic mattress

- تستخدم مطاحن ريموند الأسطوانة

- كسارة الحجر الجيري بليتشينغتون

- حار بيع كسارة الخرسانة المتنقلة

- bosch angal grinding sl no 060172755

- وين تباع ماكينه طحن الكوفي

- كسارات مجمعة من زامبيا

- آلة مطحنة دقيق حصى الجافة والرطبة ntinuous

- list of crusher plant in north bengal

- محطم آلة تجار في شمال شرق مصر

- آلات التكسير الولايات المتحدة الأمريكية

- دليل المستخدم لطحن مطحنة للأسمنت

- limestone mining conditioner

- مصنعي كسارات الصخور

- كسارة تصادمية 100 طن في الساعة كسارة المواصفات

- طاحونة الذهب آلة التعدين hst

- crusher capacity of 500 tons hour for sale

- اسعار مكن فطوطه بالصور للبيع

- طريقة معالجة تعدين النحاس

- طحن حالة الجهاز العميل منتج

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت