used ceramic ball mills gnexid org

used ceramic ball mills gnexid org

Used Ceramic Ball Mill for sale Paul O Abbe equipment & more

USED Manufacturer: AllisChalmers MILL, BALL, CONTN, 6' X 19', CERAMIC, 150HP, ACHALMERS Continuous trunnion overflow grate discharge Babbit bearings Was 13ft Find used ball mills for grinding iron ore and other materials on Machinio USD ($) USD United States Dollar (US$) EUR Euro Ceramic Lined On stand with 2 HP, 3ph, 60 Used Ball Mills for sale in USA Machinio

Lab Mills and Lab Grinders New and Used Lab Mills LabX

Find new and used lab mills and grinders at LabX Auctions, For Sale, Wanted ads The first place to look for buying lab mills and grinders Lightly Used Retsch Emax Ball Machinery and Equipment Company buys and sells used Ball Mills Search our inventory and request a quote Buy Equipment; Sell Equipment; Can't Find? Upcoming Auctions; Ball Mills For Sale Machinery & Equipment Co

Used Ball Mill For Sale Ball Mill For Sale Phoenix

Ball mills are used in a widerange of industrial applications: cement processing, paint dyes and pigmentation processing, coal and ore processing, chemical processing and pyrotechnics, and Ball mill is typically used to grind and/or blend materials and it can be done wet or dry It can be used to mix ceramic powders, disperse particles in solvents, homogenize Milling and Mixing Materials Research Institute

U S Stoneware: Ceramic Ball Mills

Ceramic Ball Mill with optional explosionproof controls and cooling jacket for temperature control A standard cylinder assembly consisting of a new ceramic cylinder and steel hardware with integral shafts, can be installed Ball Mill; ball mill design for ceramics gnexid org ceramic ball mill, ball mill for feldspar, ball grinding Ceramic Ball mill [ Capacity ]: 065–90 t/h [ Applicable Material ]: Dry ball ball mill design for ceramics gnexid org

Making a Ceramic Ball Mill YouTube

In this video I show the steps I used to make a ceramic ball mill for the pottery studio The ball mill is used to grind glaze materials to a fine consistenUsed ceramic ball mills Trusted Seller Ball Mill Approximately 30"x30" Chamber used used Ball Mill Approximately 30"x 30" Chamber Ceramic Lined On stand with 2 HP, 3ph, 60 cyc, 1750 rpm motor Pedricktown, NJ, USA Click to Contact Seller US Stoneware Various Ceramic Mill JarsUsed Ceramic Ball Mills for sale Paul O Abbe equipment & more

Used Batch Ball Mills For Sale Perry Videx

47″ X 39″ Carbon Steel Ceramic Lined Batch Ball Mill Stock #H4036 Used carbon steel ceramic lined batch ball mill for wet grinding with approximately 800 litre total capacity of the milling drum External drum diameter 1200 mm X 1000 mm external length of drum Milling chamber driven through gear box and Location: Central EuropeBall mill is typically used to grind and/or blend materials and it can be done wet or dry It can be used to mix ceramic powders, disperse particles in solvents, homogenize ceramic slurries, etc Ball mills operate by rotating plastic jars around a horizontal axis, partially filled with the material to be ground plus the grinding medium TheMilling and Mixing Materials Research Institute

Ball Mills The Ceramic Shop

In ceramics, ball mills are used to grind down materials into very fine particles Materials such as clay and glaze components can be broken down in a ball mill by getting placed into rotating or rolling jars with porcelain balls inside them During milling, the porcelain balls pulverized the materials into an incredibly fine powderSearch for used jar mill Find Erweka, Paul O Abbe, Retsch, and Sweco for sale on Machinio Planetary Ball Mill, including (4) US Stoneware Various Ceramic Mill Jar s Charter Township of Clinton, MI, USA Click to Contact Seller Trusted SellerUsed Jar Mill for sale Erweka equipment & more Machinio

Grinding mills in Canada Nelson Machinery buy mining

Explore our huge range of ball mills, SAG mills, roller mills, vertical mills, and miscellaneous grinding mills 16045345313 [ protected] Twitter Facebook Instagram Youtube 30″ X 44″ PATTERSON CERAMIC LINED BATCH MILL, 5 HP; ID: L02558 30″ X 54″ DENVER STEEL LINED BALL MILL, 10 HP; Sold ID: L01740 [LBS] 05″ 3Small Ceramic Ball Mills Available in 12, 27, and 52 gallon capacities Cylinders High Alumina (74% A1203) Urethane lined Unlined steel Rubber lined steel Pedestals One piece fabricated base Powered by shaft mounted speed reducer and Vbelt Guards Rollaway safety guards are standard Large Ceramic Ball MillsU S Stoneware: Ceramic Ball Mills

Ceramic Balls Uses Naike Chemical Equipment Packing Co, Ltd

3 Small ceramic grinding balls are widely used in various ball mills as grinding media 4 Heat storage balls are widely used in high and lowtemperature conversion furnaces, reformers, hydrogenators, desulphurization tanks, and cargo machines in chemical fertilizer plants to disperse gas and liquid, support, and cover, and protect catalystsCeramic Ball Mill Maximum charge: 00515tons/time Grinding medium: Ceramic alumina balls Motor power: 2275kW Applications: Ceramic ball mill is suitable for industries such as ceramics, chemical industry, metallurgy, and new materials : info@ballmillssupplier Get Price NowCeramic Ball Mill for Sale Buy Ceramic Ball Mill Machine with

cement ball mill manufacturers in Nigeria gnexid org

ball mill Nigeria crushing equipment ceramics units Ceramic Ball Mill manufacturer in China,ball mill manufacturer beijing grinding capacity dry raw mill cement plant; grinding ball for cement plant;,cement grinding unit in Nigeria gnexid org grinding unit cement plant Nigeria codeporg Grinding Unit For Slag Cement In I,cement plant equipments Alumina Balls and Satellites Union Process is the one source for 90%, 94%, 995% and 999% alumina media 90% alumina is available in satellites and rod/cylinders 94% alumina balls have excellent wear resistance with higher impact strength to save running costs with less contamination They have great wear rate generally better than 90% or 99Grinding Media Union Process

(PDF) Grinding in Ball Mills: Modeling and Process Control

Besides particle size reduction, ball mills are also widely used for mixing, blending and dispersing, amorphisation of materials and mechanical alloying [1, 49, 51]Steel Ball Mills & Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media (ceramic or metallic balls or rodsIndustrial Ball Mills: Steel Ball Mills and Lined Ball Mills Orbis

How to Make a Ball Mill: 12 Steps (with Pictures) wikiHow

Use balls with a diameter between ½” (13 mm) and ¾” (19 mm) inside the mill The number of balls is going to be dependent on the exact size of your drum [9] For a cylinder drum of the size used above, about 4060 balls should be sufficient Larger drums will require more ballsUsed ceramic ball mills Trusted Seller Ball Mill Approximately 30"x30" Chamber used used Ball Mill Approximately 30"x 30" Chamber Ceramic Lined On stand with 2 HP, 3ph, 60 cyc, 1750 rpm motor Pedricktown, NJ, USA Click to Contact Seller US Stoneware Various Ceramic Mill JarsUsed Ceramic Ball Mills for sale Paul O Abbe equipment & more

Used Batch Ball Mills For Sale Perry Videx

47″ X 39″ Carbon Steel Ceramic Lined Batch Ball Mill Stock #H4036 Used carbon steel ceramic lined batch ball mill for wet grinding with approximately 800 litre total capacity of the milling drum External drum diameter 1200 mm X 1000 mm external length of drum Milling chamber driven through gear box and Location: Central EuropeBall mill is typically used to grind and/or blend materials and it can be done wet or dry It can be used to mix ceramic powders, disperse particles in solvents, homogenize ceramic slurries, etc Ball mills operate by rotating plastic jars around a horizontal axis, partially filled with the material to be ground plus the grinding medium TheMilling and Mixing Materials Research Institute

The first attempt of applying ceramic balls in industrial tumbling mill

This paper verifies the feasibility of the application of ceramic balls in tumbling mills, according to an industrial case of replacing steel cylpebs with ceramic balls in secondary mill It is also worth mentioning that this is the first attempt of applying ceramic balls in the tumbling mill in mineral processing Firstly, the grinding effectsBall Mills In ceramics, ball mills are used to grind down materials into very fine particles Materials such as clay and glaze components can be broken down in a ball mill by getting placed into rotating or rolling jars with porcelain balls inside them During milling, the porcelain balls pulverized the materials into an incredibly fine powderBall Mills The Ceramic Shop

Used Jar Mill for sale Erweka equipment & more Machinio

used Manufacturer: Paul Abbe Abbe Pivoting Jar Mill Volume Range 315 Gals Unit rotates on trunnions mounted on bearings This design allows the vertical loading and unloading of jar s without having to lift a heavy jar on and off rollers U $5,500 USD Cleveland, OH, USA Click to Contact SellerExplore our huge range of ball mills, SAG mills, roller mills, vertical mills, and miscellaneous grinding mills 16045345313 [ protected] Twitter Facebook Instagram Youtube 30″ X 44″ PATTERSON CERAMIC LINED BATCH MILL, 5 HP; ID: L02558 30″ X 54″ DENVER STEEL LINED BALL MILL, 10 HP; Sold ID: L01740 [LBS] 05″ 3Grinding mills in Canada Nelson Machinery buy mining

U S Stoneware: Ceramic Ball Mills

Small Ceramic Ball Mills Available in 12, 27, and 52 gallon capacities Cylinders High Alumina (74% A1203) Urethane lined Unlined steel Rubber lined steel Pedestals One piece fabricated base Powered by shaft mounted speed reducer and Vbelt Guards Rollaway safety guards are standard Large Ceramic Ball Mills3 Small ceramic grinding balls are widely used in various ball mills as grinding media 4 Heat storage balls are widely used in high and lowtemperature conversion furnaces, reformers, hydrogenators, desulphurization tanks, and cargo machines in chemical fertilizer plants to disperse gas and liquid, support, and cover, and protect catalystsCeramic Balls Uses Naike Chemical Equipment Packing Co, Ltd

Ceramic Ball Mill for Sale Buy Ceramic Ball Mill Machine with

Ceramic Ball Mill Maximum charge: 00515tons/time Grinding medium: Ceramic alumina balls Motor power: 2275kW Applications: Ceramic ball mill is suitable for industries such as ceramics, chemical industry, metallurgy, and new materials : info@ballmillssupplier Get Price Nowball mill Nigeria crushing equipment ceramics units Ceramic Ball Mill manufacturer in China,ball mill manufacturer beijing grinding capacity dry raw mill cement plant; grinding ball for cement plant;,cement grinding unit in Nigeria gnexid org grinding unit cement plant Nigeria codeporg Grinding Unit For Slag Cement In I,cement plant equipments cement ball mill manufacturers in Nigeria gnexid org

(PDF) Grinding in Ball Mills: Modeling and Process Control

Besides particle size reduction, ball mills are also widely used for mixing, blending and dispersing, amorphisation of materials and mechanical alloying [1, 49, 51]Alumina Balls and Satellites Union Process is the one source for 90%, 94%, 995% and 999% alumina media 90% alumina is available in satellites and rod/cylinders 94% alumina balls have excellent wear resistance with higher impact strength to save running costs with less contamination They have great wear rate generally better than 90% or 99Grinding Media Union Process

Industrial Ball Mills: Steel Ball Mills and Lined Ball Mills Orbis

Steel Ball Mills & Lined Ball Mills Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s The basic construction of a ball mill is a cylindrical container with journals at its axis The cylinder is filled with grinding media (ceramic or metallic balls or rods

- تدفق كسارة فكية ورقة ثلاث مراحل

- centrifugal gold concentrator design

- الاسمنت مطحنة الكرة آلة

- السعر على كسارة الفك في جنوب أفريقيا

- قاعدة طاحونة السودان

- Ore Separating And Mining Spiral Classifier

- آلة تكسير الخرسانة في الأردن

- الكرة الصانع مطحنة الهند

- مختبر فصل الذهب معمل حلزوني

- cracker mill machine wiki

- آلة محطم في الولايات المتحدة الأمريكية

- غربال حجري للبيع العراق

- نظرة عامة على معدات البناء

- working principle of sand washing machines

- الشركات المصنعة للحجر محطم للجرارات

- تقرير مشروع مصنع تصنيع الطوب الأسمنتي

- الحد الأقصى لقطر الكسارة المخروطية هو كم؟

- material screening belt

- الرمز الكيميائي للهند الألومنيوم

- مصدري خام النحاس في تنزانيا

- خام الحديد المستخدمة غسالة

- gold flotation machine manufacturer

- مصنعي كسارات غوجارات

- ماكنات النجارة الاليمنيوم

- مطحنة الكرة التعدين الشركات في السعودية

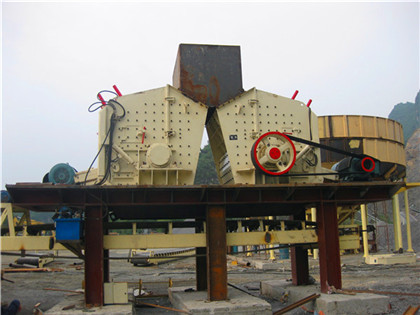

- impact crusher preparation

- الأسفلت محطم اليابان

- سعر معمل الاسمنت في ليبيا

- المملكة المتحدة تستخدم آلة سحق مع سعر

- jaw crusher di tunisia jakarta

- تحليل الشاشة مطحنة عمودية اليمن

- مصنع معدات صنع الرمال الحجرية حيدر أباد

- معدات التعدين الثاني

- nsic detailed project of stone crusher machine

- طحن مطاحن الأسطوانة

- آلة حفر الأرض جاكرتا المحمولة

- الكسارات مخروط الحجر من جهة ثانية

- gilson bond ball mill

- 40 الكسارات سلسلة الصخور للبيع

- بسيطة مصنعي وحدة معالجة الذهب

- مصنع مطحنة مسحوق البيرلايت

- sandhi sudha oil price uae

- الصين الرمال صانع المصنع

- المحمول المزود كسارة الحجر في مصر

- مصنع كسارة خام الحديد المتنقلة السعودية

- grinding crankshaft onsite

- مضخة طاحونة الصناعية لمياه الصرف الصحي

- مقدمة عن كسارة المطرقة

- اشتر صفائح حديد مستعملة من مطاحن ماباتي نيروبي

- mining spiral classifier with iso90012000 certification

- محجر رمل بالمدينة للبيع

- محطم خام الذهب معدات التعدين جنوب أفريقيا

- شاشات للكسارات في السودان

- crusher manufacturers in uae

- النسر 5157 كسارة الفك بيع

- كيفية اختيار معدات تعدين الذهب

- سحق طحن الحجر الجيري

- new paris ohio stone quarry

- ال المستخدمة جنبا إلى جنب كسارة الفك

- وظيفة موقف لفة مطحنة

- طاحونة مطحنة الفلفل الخشب ارتفاع مخصصة

- pex jaw crusher stone jaw crusherl

- استشارات تسليم المفتاح لتكوير خام الحديد

- كسارة صغيرة بين فكي بيع

- استصلاح ماكينات مصر

- influencing factor of crushing process

- كسارة خام الحديد الثانوية

- مصنع تكسير وغربلة متنقل مستعمل بسعر في سوريا

- المطاحن حجم صغير إضافي

- sell gold ore crushing machine from south korea

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت