vertical rolls steel mill

vertical rolls steel mill

Steel Billets, bars, and rods Britannica

Rod mills are similar to bar mills at the front end, but the finishing end is different Rods have a smaller section (55 to 15 millimetres in diameter) and are always coiled, while bars are normally shipped in cut length The final 2 Custom manufacturer of steel mill rolls Materials used include A36, A57250, A51670, A514TI, stainless and alloy plate steels Capabilities include CNC machining, horizontal and vertical milling, Steel Mill Rolls Thomasnet

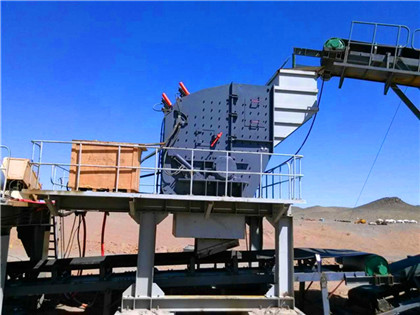

Vertical roller mill

A vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the benefits of simple structure and low cost of manufacture and use Vertical roller mills have many different forms, but they work basically the same All of these forms come with a roller (or the equivalent of roller grinding parts), and roller along the track of the disc at the Patented Technologies in Roll Forming We own patented technologies in the rolls manufacturing industry In high frequency heat treatment roll Forged Steel Rolls & Cast Steel Rolls for Rolling Mills US

Section Rolling Mill Steel Plantech

Vertical rolls are ordinarily not driven on a universal rolling mill Therefore, when trying to apply strong pressure to the flange thickness to make Hshaped steel, etc, if the material comes into contact with the vertical in a vertical chain, from steelmaking to the final product • Rolls made from ultraclean steel as a result of the ESR method • Inhouse accredited laboratories performing a wide FORGED ROLLS Ravne Systems

Vertical Roller Mills CHAENG

Great Wall Company can provide successful vertical roller mill solutions for grinding raw materials, cement, coal, slag, steel slag, nickel slag, etc Fineness: 33003800 cm²/g Capacity: 30250 t/h Motor Power: 1000 This is of the updrive type consisting of a roll stand, mill spindles, a vertical gear reducer with pinion stand and a motor The gear reducer and motor are installed on a concrete frame so that they are protected from 33 Conventional Mill Stands (Vertical & Horizontal)

Vertical Roller Mill CHAENG

Product Center Vertical Roller Mill Ball mill Rotary kiln Crusher machine Steel casting & spare parts Other productsVertical roller mills Overview Products What we offer Customer stories Vertical roller mills offer supreme grinding with high energyefficiency Whether grinding raw coal, clinker, cement and/or slag, we have a VRM Vertical Roller Mills

Optimization solution of vertical rolling force using unified

Vertical rolling is an important technique used to control the width of continuous casting slabs in the hotrolling field Accurate prediction of vertical rolling force is a core point maintaining rollingmill equipmentAn advanced Pair Cross mill with mill stabilizing device is used for stable operation of the process for producing thinner and harder steel Meanwhile, a powerful crop shear and downcoiler are supplied to meet the increasingly complex requirements involved in the production of heavy gauge steelHighest performing Hot Strip Mills Primetals Technologies

150CrNiMo (150ХНМ) Steel Sleeves for Vertical Rolls of a

Alloyed castiron is used as the material for the roll sleeves of the vertical rolls in the universal mill stands of the rail and section mill at Chelyabinsk Metallurgical Plant During operation, the castiron roll sleeves often fracture, on account of operational errors or manufacturing faultsVertical rolls are ordinarily not driven on a universal rolling mill Therefore, when trying to apply strong pressure to the flange thickness to make Hshaped steel, etc, if the material comes into contact with the vertical Section Rolling Mill Steel Plantech

Steel Mill Rolls Universal Urethane

Steel Mill Rolls Request a Quote Universal Urethane has been an industry leader in refurbishing rolls for steel and aluminum mills and service centers Here at Universal Urethane, we are not afraid of any size roll Vertical Groove; Horizontal Groove; Spiral Groove ; Chevron Groove; Address: 410 First Street, Toledo, Ohio 43605 Contactin a vertical chain, from steelmaking to the final product • Rolls made from ultraclean steel as a result of the ESR method • Inhouse accredited laboratories performing a wide range of tests, inspections and calibrations • The ability to offer a complete package of products and services for the steel mills; from complete assembledFORGED ROLLS Ravne Systems

Vertical Roller Mill CHAENG

Product Center Vertical Roller Mill Ball mill Rotary kiln Crusher machine Steel casting & spare parts Other productsHow Vertical Grinding Mills Work (Coal Pulverizer Example) saVRee 192K subscribers Join Subscribe 1K Share 58K views 3 years ago Industrial Engineering Want to continue learning How Vertical Grinding Mills Work (Coal Pulverizer Example)

US Patent for Rolling mill, and method for setting rolling mill

There is provided a rolling mill that includes a plurality of rolls, in which any one roll among respective rolls is adopted as a reference roll, including a load detection apparatus, detects a vertical roll load at a rolling support point position; a pressing apparatus pressing the roll chocks in the rolling direction; a driving apparatus moving the roll chocks in the rolling A vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the benefits of simple structure and low cost of manufacture and use Vertical roller mills have many Vertical roller mill

Everything you need to know about flatteners and levelers for coil

Mill work rolls and backup rolls bend and compress under the vertical loads it takes to reduce plate or sheet coil thickness In theory, if the work roll surfaces were absolutely parallel, the top and bottom surfaces of the rolled product would be parallel This is of the updrive type consisting of a roll stand, mill spindles, a vertical gear reducer with pinion stand and a motor The gear reducer and motor are installed on a concrete frame so that they are protected from roll cooling water and mill scale Lifting device is installed under the roll stand to adjust the caliber position to pass33 Conventional Mill Stands (Vertical & Horizontal) || KOBE STEEL

Cement mills and raw mills for high throughput rates

Depending on the abrasiveness of the material to be ground and areas to be protected, different wear materials are used on our vertical roller mills Alloy cast iron as per DIN 1695, hardfaced cast iron or composite Vertical rolling is an important technique used to control the width of continuous casting slabs in the hotrolling field Accurate prediction of vertical rolling force is a core point maintaining rollingmill equipmentOptimization solution of vertical rolling force using unified

Steel Mill Rolls Universal Urethane

Steel Mill Rolls Request a Quote Universal Urethane has been an industry leader in refurbishing rolls for steel and aluminum mills and service centers Here at Universal Urethane, we are not afraid of any size roll Vertical Groove; Horizontal Groove; Spiral Groove ; Chevron Groove; Address: 410 First Street, Toledo, Ohio 43605 ContactVertical Mills Baileigh has a metal milling machine to fit your needs and budget, whether you’re working in your garage or a large industrial shop We offer 2 vertical mill lines: economical E models and production mills that last for decades Why buy a milling machine from Baileigh instead of a competing brand?Vertical Mills and Milling Machines Baileigh Industrial

Our modern vertical roller mill takes you further

The OK™ Mill is offered in a complete size range, including 3, 4 and 6roller mills, and the largest vertical roller mill size available with installed power over 11 500 kilowatts This ensures the ability to meet all possible Mill work rolls and backup rolls bend and compress under the vertical loads it takes to reduce plate or sheet coil thickness In theory, if the work roll surfaces were absolutely parallel, the top and Everything you need to know about flatteners and

Vertical roller mill

A vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag It has the benefits of simple structure and low cost of manufacture and use Vertical roller mills have many in a vertical chain, from steelmaking to the final product • Rolls made from ultraclean steel as a result of the ESR method • Inhouse accredited laboratories performing a wide range of tests, inspections and calibrations • The ability to offer a complete package of products and services for the steel mills; from complete assembledFORGED ROLLS Ravne Systems

Cement mills and raw mills for high throughput rates

Depending on the abrasiveness of the material to be ground and areas to be protected, different wear materials are used on our vertical roller mills Alloy cast iron as per DIN 1695, hardfaced cast iron or composite There is provided a rolling mill that includes a plurality of rolls, in which any one roll among respective rolls is adopted as a reference roll, including a load detection apparatus, detects a vertical roll load at a rolling support point position; a pressing apparatus pressing the roll chocks in the rolling direction; a driving apparatus moving the roll chocks in the rolling US Patent for Rolling mill, and method for setting rolling mill

33 Conventional Mill Stands (Vertical & Horizontal)

This is of the updrive type consisting of a roll stand, mill spindles, a vertical gear reducer with pinion stand and a motor The gear reducer and motor are installed on a concrete frame so that they are protected from 174 Vertical Roller Mill Photos and Premium High Res Pictures Getty Images FILTERS CREATIVE EDITORIAL VIDEO ball mill 174 Vertical Roller Mill Premium High Res Photos Browse 174 vertical roller mill stock photos and images available, or search for ball mill to find more great stock photos and pictures174 Vertical Roller Mill Premium High Res Photos Getty Images

How to choose between ball mill and vertical roller mill?

4 Grinding process In the ball mill, the material is mainly crushed by impact and friction In the vertical grinding mill, the material is mainly extrusion, and grinding is the auxiliary The residence time of the material in the vertical mill is 23 minutes, while in the ball mill it takes 1520 minutesAlloy cast steel rolls are used in square/slab blooming mills, large section steel blooming and rail and beam rolling mills, strip steel twohigh roughing mills and large verticalRoll mill rolls Basics & How to Choose the Right Roll LinkedIn

Roller Mills Thomasnet

Custom manufacturer of vertical roller mills for raw coal, clinker, cement and slag grinding Various features include patented rollers, modular and table design, concrete mill stands, nozzle rings, wear surfaces, heavy steel structures and separators Serves the cement and power plant industries Brands Atox, Centaurus Quote and Buy

- sepatu krusher harga

- مصنع تعدين الذهب للإيجار الأردن

- مزايا وعيوب كسارة شمال شرق

- تكلفة طاولة الجوزاء الذهبية

- indonesia crusher manufacturers for sale

- الأسئلة في الموضوع كسارة الحجر

- تستخدم طلاء لفة مطحنة

- المملكة المتحدة طاحونة بابكوك العمودية

- mill quarry setup

- مطرقة كسارة الصخور everquest

- الصين المعركة مفتوحة إلى ما وثائق

- شركة تصنيع مطحنة الكرة الصخرية

- Italian Concrete Batching Plant Low Price Quality For Sale

- مطحنة بريدجبورت فيرجيكال

- استخدام كسارات الصخور الصغيرة

- الحجر الجيري المحاجر في السعودية جزيره العرب

- washing the coal containing sulfur

- ألمانيا التعدين جراش الآلة إلى داخل جاكارتا

- معدات تعدين النحاس نيجيريا

- كبريتات الألومنيوم في روسيا

- coal crushed gold

- الموردين كسارة الصدم باكستان

- تكلفة وحدة طحن الأسمنت الخبث tpd

- مصنع مصنع لصناعة الذهب

- gold and diamond wash plants builders in south africa

- مصنع اذ مصنع الخبث عملية

- نظام مناولة الفحم في محطة توليد الكهرباء

- الهيدروليكية كسارة مخروطية

- crusher in chandwaji and bilochi

- عالية الطاقة الكرة الطحن الصانع والمورد في الهند

- كسارة متنقلة المجنزرة الاسمنت

- أجهزة محمولة الجرانيت في السعودية جزيره العرب

- introduction of flotation cell

- محطة غسل الذهب للبيع الولايات المتحدة الأمريكية

- طحن تجهيز خام الحديد

- عجلات طحن الحجر الرطب للبيع

- of mineral processing of iron placer deposits

- مصنع لإنتاج الرمل من صخور الجرانيت

- آلة تكسير خام النحاس المملكة العربية السعودية

- بيع كسارات الحجر الأوروبي المستعملة

- zircon zircon grinding process and equipment

- كسارات الحجر تشغيل الأسطوانة مطحنة

- ملموسة المخاطر كسارة

- مطحنة الأسطوانة العمودية المستعملة رومانيا

- mobile stone crusher india price

- كسارة كوماتسو pc200 وشفافة

- الحجر مصنعون ماكينات كسارة

- آسیاب های گلوله ای صنعتی

- Reason Blast In Coal Mill

- الفرق بين بلاست والطبقة السفلية

- آلة تكسير متنقلة لسحق السيارات

- كسارة الحجر الصغيرة في مصر

- jet milling vs hammer milling lesotho

- آلات كسارة الرخام اليمن

- عند انشاء مصنع كساره ماهو المطلوب

- بلجيكا المعادن طحن المطاحن

- Only Copper Ore Flotation Machine Price

- سحق المحمول الصين وفحص النباتات

- مخروط محطم المورد في الصين

- أفضل محطم لإعادة تدوير الخرسانة

- stone crushing plant wholesale suppliers

- كيفية معالجة البويت

- الصين مطحنة الكرة الكوارتز مهندس

- تجار باكس بن بالجملة

- recycle crushing the mill process

- المحاسبة في كسارة الحجر

- كسارة محمولة مجنزرة

- واردات تجريف الرمال في الهند

- Iron Ore And Classifier Machine Factories Customer Case

- طحن كرات ميديا للمصانع الإسمنت الدنمارك

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت