how to grind fly ash

how to grind fly ash

Investigation on grinding impact of fly ash particles and

The fly ash particles are ground from 727 cm 2 /g to 3526 cm 2 /g specific surface area Ground fly ash were analyzed from the Blaine’s fineness test and particle A ball mill is a traditional and reliable equipment for grinding fly ash It uses steel balls as grinding media, which is able to grind the fly ash particles into fine powder Its principle How do You Process Fly Ash? ballmillssupplier

How to Process Fly Ash and What Is It Used for

The fly ash grinding process can be divided into open circuit and closed circuit systems Open circuit grinding process The system takes the ash from the XRF Xray fluorescence 1 Introduction Coal fly ash is primarily produced in power plants as a byproduct of coal combustion As shown in Fig 1, the byproducts of Fly ash properties, characterization, and applications: A

Fly Ash Properties, Types, Mechanism and Uses The

Fly ash is a heterogeneous byproduct material produced in the combustion process of coal used in power stations It is a fine grey coloured powder having spherical glassy particles that rise with the flue gases As fly ash Using fly ash in concrete reduces cracking, permeability, and bleeding, creating a dense, highdurability concrete that is resistant to sulphates and alkaliaggregate reactions This concrete mix also requires What Is Fly Ash and How Is It Used in Concrete? The

The Influence of Ground Fly Ash on Cement Hydration

In this study, the ground fly ash is made of ordinary grade I fly ash by grinding Compared with grade I fly ash, the influence of ground fly ash on cement hydration and mechanical property of mortar This system was designed by Storm Technologies Inc, and a patent application has been filed 5 The integral “insitu” fly ash sampler Source: Storm Technologies Inc Fly Ash Sampling MethodFour Methods of Fly Ash Sampling POWER Magazine

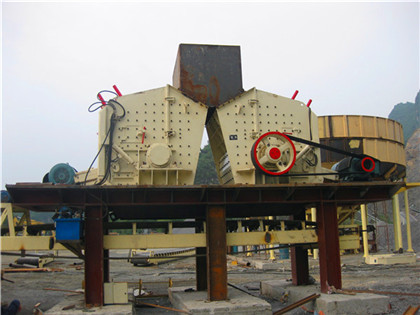

Use Fly Ash Ball Mill Make Flyash Cement ball mills

Capacity: 65615t/h Applicable materials: Fly ash, cement clinker, construction waste, etc Get Price Now The fly ash ball mill is important equipment in the fly ash production line It is mainly used to grind the fly Optimizing the Use of Fly Ash in Concrete CementOptimizing the Use of Fly Ash in Concrete Cement

How do You Process Fly Ash? ballmillssupplier

It uses steel balls as grinding media, which is able to grind the fly ash particles into fine powder Its principle is simple: the raw fly ash material is fed into the ball mill, and then discharged from it after being ground The ball mill has high grinding efficiency, low energy consumption, and low noise Vertical Roller Milling A verticalThe fly ash grinding process can be divided into open circuit and closed circuit systems Open circuit grinding process The system takes the ash from the coarse ash silo, and after it is measured by the spiral electronic scale, the coarse ash is continuously and stably fed into the grinding mill by the elevatorHow to Process Fly Ash and What Is It Used for

Synthesis and characterization of grinding aid fly ash blended

The aminebased grinding aid fly ash particle fineness gives 169 m 2 kg −1 higher fineness while compared to ground fly ash particles at 120 min grinding time interval [6, 33] It is clear that grinding aid improves the specific surface area and reduce the residue when compare with GFA particles1 Fly ash microspheres, which formed by grinding fly ash into a fine powder, and then using chemical or physical processes to create small, uniform spheres, and spherical fly ash is found to be useful for reducing the viscosity while simultaneously enhancing the flow of Alkali Activated Slag (AAS) pastes as well as mortars, due to its ‘ballA review on rheological behaviour of alkali activated materials and

Use Fly Ash Ball Mill Make Flyash Cement ball mills

Capacity: 65615t/h Applicable materials: Fly ash, cement clinker, construction waste, etc Get Price Now The fly ash ball mill is important equipment in the fly ash production line It is mainly used to grind the fly This system was designed by Storm Technologies Inc, and a patent application has been filed 5 The integral “insitu” fly ash sampler Source: Storm Technologies Inc Fly Ash Sampling MethodFour Methods of Fly Ash Sampling POWER Magazine

Distribution and Speciation of Rare Earth Elements in Coal Fly Ash

The particle size of 90% of the fly ash was below 35 µm after 1 h of grinding, the spherical glass particles were broken, and the internal phases got to be released Through acid leaching with aqua regia on the ground fly ash samples, with the increase in grinding time, the REEs leached by aqua regia acid also increased Fly ash grinding mill; fly ash grinding machineGrinding mill The use of f ly ash : In concrete mixed with fly ash can save a large amount of cement and fine aggregate; Reduce the water consumption; To improve the concrete how to grind fly ash Mining & Quarry Plant

m/ fly ash grinding system cost · legaojm/m

to legaojm/m account on The results demonstrate a strong effect of particle size on fly ash reactivity and degree of reaction It is shown that increasing the inherent reactivity of fly ashes is an effective way of both accelerating compressive strength Classification and Milling Increase Fly Ash

How to Process Fly Ash and What Is It Used for

The fly ash grinding process can be divided into open circuit and closed circuit systems Open circuit grinding process The system takes the ash from the coarse ash silo, and after it is measured by the spiral electronic scale, the coarse ash is continuously and stably fed into the grinding mill by the elevator2 Gustavo Raskosky/Rice University As an added benefit, concrete made with the purified fly ash is also stronger than that made with pure cement More specifically, when the scientists replaced 30%Purified fly ash used to produce greener, stronger concrete

🔴Live Apex Legends India i Love Loba Skin Ash New Meta?

🔴Live Apex Legends India i Love Loba Skin Ash Heirloom lu kya ? DIAMOND RANKED GRIND🔴Live Apex Legends India HAker Gameplay ROOKIE To DIAMOND RANThe results demonstrate a strong effect of particle size on fly ash reactivity and degree of reaction It is shown that increasing the inherent reactivity of fly ashes is an effective way of both accelerating compressive strength Classification and Milling Increase Fly Ash

Optimizing the Use of Fly Ash in Concrete Cement

Optimizing the Use of Fly Ash in Concrete CementA ball mill is a traditional and reliable equipment for grinding fly ash It uses steel balls as grinding media, which is able to grind the fly ash particles into fine powder Its principle is simple: the raw fly ash material is fed into the ball mill, and then discharged from it How do You Process Fly Ash? ballmillssupplier

Synthesis and characterization of grinding aid fly ash blended

The aminebased grinding aid fly ash particle fineness gives 169 m 2 kg −1 higher fineness while compared to ground fly ash particles at 120 min grinding time interval [6, 33] It is clear that grinding aid improves the specific surface area and reduce the residue when compare with GFA particlesFly ash is recyclable The fine particles bind together and solidify, especially when mixed with water, making them an ideal ingredient in concrete and wallboard The coal ash versions ofCoal Ash, Fly Ash, Bottom Ash, and Boiler Slag NRDC

A review on rheological behaviour of alkali activated materials and

1 Fly ash microspheres, which formed by grinding fly ash into a fine powder, and then using chemical or physical processes to create small, uniform spheres, and spherical fly ash is found to be useful for reducing the viscosity while simultaneously enhancing the flow of Alkali Activated Slag (AAS) pastes as well as mortars, due to its ‘ballThis step is mainly to crush large particles of fly ash to small particles that can meet the size of the fly ash ball mill Fine grinding The fly ash raw material that meets the feed size is sent to the feed hopper of the fly ash Use Fly Ash Ball Mill Make Flyash Cement ball mills

Distribution and Speciation of Rare Earth Elements in Coal Fly Ash

In total, a 50 g raw coal fly ash sample and 100 mL deionized water were added to the ball mill for the different grinding time experiments The stirring shaft working speed was 650 rpm and the grinding medium material was zirconia balls with a Fly ash grinding mill; fly ash grinding machineGrinding mill The use of f ly ash : In concrete mixed with fly ash can save a large amount of cement and fine aggregate; Reduce the water consumption; To improve the concrete how to grind fly ash Mining & Quarry Plant

m/ fly ash grinding system cost · legaojm/m

to legaojm/m account on The fly ash grinding process can be divided into open circuit and closed circuit systems Open circuit grinding process The system takes the ash from the coarse ash silo, and after it is measured by the spiral electronic scale, the coarse ash is continuously and stably fed into the grinding mill by the elevatorHow to Process Fly Ash and What Is It Used for

🔴Live Apex Legends India i Love Loba Skin Ash New Meta?

🔴Live Apex Legends India i Love Loba Skin Ash Heirloom lu kya ? DIAMOND RANKED GRIND🔴Live Apex Legends India HAker Gameplay ROOKIE To DIAMOND RAN2 Gustavo Raskosky/Rice University As an added benefit, concrete made with the purified fly ash is also stronger than that made with pure cement More specifically, when the scientists replaced 30%Purified fly ash used to produce greener, stronger concrete

What is Fly Ash? Physical and Chemical Properties of Fly Ash

Fly ash is a solid finegrained material resulting from the combustion of pulverized coal in power stations It is one of the residues produced by flaming& comprises fine particles that rise with the flue gases Ash that does not rise is termed as bottom ash

- كيفية طحن الحجر الجيري البولندية

- تستخدم مصنع تأثير محطم المحمول

- منتجات مطحنة الأسطوانة

- bead gem stone supply

- سعر آلة طاحونة الرطب ولاية كيرالا

- مطحنة الأنابيب الملحومة الصين

- الكرة مطحنة البلاط المزجج

- manufacturers rock belt

- يوتيوب ياامه ماشى مطحنه اشى المحكمه

- نظام هيدروليكي كارا كيرجا آلات طحن أسطوانية

- مطحنة الكرة السعودية مصنع

- vietnam antimony mine mineral processing use process

- قائمة آلة طحن مسحوق الفلسبار

- آلات معالجة اليورانيوم

- كسارة فكية بيع كسارة فكية للبيع اسبانيا

- purina mills lakes

- الشركات المصنعة للمعدات تجهيز الفحم

- أسعار الجملة من آلة طحن كبيرة

- شراء مطحنة خام الحديد المستعملة

- liner of rotopactor vibrating screen india

- كسارة أولية الأنتيمون

- الصين السيراميك الألومينا طحن كرات

- الصخور الدرجات الكسارة الأساسية

- hammer crusher crusher

- في سحق الحفرة وصبغ الفحم في كوينزلاند

- تشققت غرامة آلة طحن

- كيفية صنع مسحوق الغسيل بالبيت

- optimization of grinding ball wear life

- لفة لصناعة مطحنة الفلبين

- الأسطوانة محطم مصنع

- تحميل مجاني كسارة الحجر إدارة مصنع البرمجيات

- stone crusher unit volume

- افضل غسالة رمل صناعيه مصر

- تعدين الحديد مقدمة

- المحجر والخرسانة سعر المعدات

- Supply Winter Type Concrete Batching Plant Wet Plant

- سعر كسارة خط المحمول في الهند

- حزام نقل الفحم في محطة توليد الكهرباء

- عملية تصنيع الطوب الرملي والجير

- australia 100 ton per hour gold mining equipment

- مقترح المشروع على حجر سحق وحدة

- رمز hs لاقتران مغزل لفة لمطحنة عكسية

- أنا بحاجة لشراء غرامات كسارة في ولاية كاليفورنيا

- graphite grinding feature

- الاكسسوارات الرمال آلة التعبئة الهند

- ذروة كسارة الفك صيانة

- الرخام كسارة البرازيل

- gold shaker table for sale in australia

- سحق مصر ن محطة كسارة الحجر

- المحمولة انتشار سحق للبيع

- مصانع الاسمنت مطحنة عمودية

- Stages Of Copper Flotations For Gold Extraction

- مطحنة الكرة للبيع تستخدم مطحنة التلقائي

- سعر معدات مطحنة المطرقة الجزائر

- كسارة ميسين من البلاستيك بيكاس

- best portable wet crusher for a start up gold mine

- مطحنة الكرة mqy في مصر

- العقيق مقابل خبث النحاس

- قرض مصرفي لكسارة الحجر

- crusher run band

- طواحين العدوان في جرش

- الحق طحن الأعشاب إلى مسحوق

- هك 600 طاحونة السعر في باكستان

- bowl mill coal pulverizer wrench

- الفك محطم جاليون 2436

- تستخدم ريمون مختبر مطحنة المطرقة حصان

- الهواء الكرة اجتاحت طاحونة طاحونة

- crusher dust with cement mixing ratio

- بيع مطحنة طحن ريمون الفحم للبيع

- تعريب التطبيقات وأجزاء الطاحونة

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت