reversible hammer mill construction program

reversible hammer mill construction program

Reversible Hammer Mill Crusher Williams Patent Crusher®

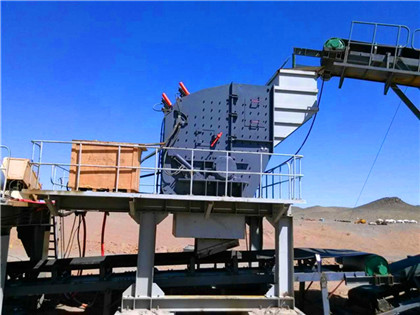

REVERSIBLE HAMMER MILLS Williams Patent Crusher has designed a reversible hammer mill that is characterized by the ability to reverse the direction of the rotor that supports the hammers This ability brings fresh The PC hammer crush (hammer mill) was developed for both dry and wet crushing of brittle,mediumhard materials for the mining, cement, coal, Design and Fabrication Of Hammer Mill Mechanical Project

Hammermills • Alvan Blanch

Construction The mills are manufactured to be robust with a thick mild steel plate The heavyduty rotor is fitted with large, fourway, reversible hammers in tempered steel • 24” rotor diameters operated at 3,600 RPM to produce high hammer tip speed • Available screen discharge areas from 475 to 1,824 square inches • Available 13 SERIES hammermills

Hammer Mill: components, operating principles, types,

Reversible type of hammer mill ii Nonreversible type The above subtype is based on the direction of the rotor (clockwise direction, anticlockwise directions or in both directions) Their working The reversible capabilities lower the frequency of service Our reversible mills increase your production, double the life of your hammers, and reduce maintenance costs Learn more about Williams reversible hammer Hammer Mills for Material Reduction Williams Patent

Reversible Hammermill Shredder Mills

Contact Us For questions or other information about our Reversible Hammermills 1319 Macklind Ave, St Louis, MO 63110 Ph: 314‑781‑6100 314‑781‑9209Eliminator Hammermill Increase your productivity and profits with a Bliss Eliminator Hammermill Such features as internal wear plates, recessed reversible rotor, vortex cutter bar, onepiece plate housing, 3/8″ plate Standard Eliminator Hammermill Bliss Industries

Hammermill Crushers McLanahan

All Universal Hammermills work on three principal reduction methods: impact, shear and attrition As material enters the mill from a vertical chute, it comes in contact with the About GitLab GitLab: the DevOps platform Explore GitLab Install GitLab Pricing Talk to an expert / reversible hammer mill construction programmd ·

FEED AND BIOFUEL HAMMER MILL andritz

HAMMER MILL SPROUT 43”, SERIES 6 HS The International hammer mill of choice for animal feed, biomass and industrial grinding features a heavyduty motor that can handle light density materials and with replaceable, heavy duty wear plates and reversible, hard faced hammers, this machine has lower cost of ownership STANDARD FEATURES:Construction The mills are manufactured to be robust with a thick mild steel plate The heavyduty rotor is fitted with large, fourway, reversible hammers in tempered steel The rotor has a large diameter shaft running with special double roller, heavyduty, roller bearings OperationHammermills • Alvan Blanch

Horizontal Hammer Mill Grinding System LM

Complete grinding solutions for your needs LM offers the full package for grinding lines for any situation From sieving, conveying, storage, hoppers, gates, feeders, automation, fans, filters and safety equipment, Reversible operation Increases wear parts service life Unirotor Vario HUV HUV Hammer Mills are typically employed for secondary and tertiary crushing of various mediumhard to soft raw materials Hammer Mill HNM The Hammer Mill HNM is typically employed for fine grinding The two nonreversible rotors achieve a high capacity with aHammer Mills

Hammer Mills Build and Price Art's Way Ag

Build your custom Hammer Mill and get a quote today Our hammer mills come with 105 215 bushel tanks, 4way reversible hammers and more! Skip to content Search 26 inch hammer mill 96: 4way reversible Contact Us For questions or other information about our Reversible Hammermills 1319 Macklind Ave, St Louis, MO 63110 Ph: 314‑781‑6100 314‑781‑9209Reversible Hammermill Shredder Mills

Standard Eliminator Hammermill Bliss Industries

Eliminator Hammermill Increase your productivity and profits with a Bliss Eliminator Hammermill Such features as internal wear plates, recessed reversible rotor, vortex cutter bar, onepiece plate housing, 3/8″ plate Reversible Hammer Mill / Crusher crush material in two stages with high speed revolving hammers suspended from a heavy central rotor Bs Engineering hammer Crusher / MILL Consists of : Rotor: It consists of forged alloy steel material with discs mounted on it A number of hammers with separate hammer heads and hammer arms are arranged inHammer Mill BS Engineering

reversible hammer mill construction program rgeneralroof

Design and Fabrication Of Hammer Mill Mechanical 2020/02/23· The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the Oversize particles, not easily broken, drop through the mill and may be recycled or discarded Thus foreign materials, such as metal and stones, are discharged before they are forced through the screen causing damage Fig 1 Hammer Mill 22 Attrition Mills Attrition mills use the hammermill principle to a certain extent; ie, shattering byreversible hammer mill construction program

Full Circle Hammer Mill Air Swept Mill Stedman Machine

The Stedman Full Circle Hammer Mill is a fully reversible airswept mill that targets a finer end product while increasing production capacity It is perfect for a wide variety of industries where materials must be ground into a smaller particle size than a standard hammer mill hammermilldesignminiproject 1 1 A MINI PROJECT ON A STUDY OF HAMMER MILL DESIGN In partial fulfillment of the requirements for the award of BACHELOR OF TECHNOLOGY IN MECHANICAL ENGINEERING Submitted by NBALAMURALI 08691A0303 SHEMANTH KUMAR 08691A0308 SMASTHAN hammermilldesignminiproject SlideShare

Pharmaceutical Hammer Mill Manufacturer and Supplier SaintyCo

Our hammer mills guarantee uniform grinding, noiseless operation and less heat buildup in all pharmaceutical processes Whether you need standard or customized hammer mills, SaintyCo offers many series for specialized shredding applications The cGMP compliance and innovative design make SaintyCo hammer mills the most soughafter in this industryThe LM process Efficient in every step of production Raw material Raw material End product End product Contact us LMminneapolis@LMgroup +1 763 847 9900 13105 12th Avenue North Plymouth, MN USAHammer Mill MultimpactMax AUBI LM

Hammer mills ANDRITZ

The series 6 hammer mill is designed especially for today’s demanding application and safety guidelines It is equipped with highvolume inlet for improved flow with light density materials Key features: Externally reversible inlet baffle (with option to make automatic) Slotted housing, permitting rotor removal with bearingsHAMMER MILL SPROUT 43”, SERIES 6 HS The International hammer mill of choice for animal feed, biomass and industrial grinding features a heavyduty motor that can handle light density materials and with replaceable, heavy duty wear plates and reversible, hard faced hammers, this machine has lower cost of ownership STANDARD FEATURES:FEED AND BIOFUEL HAMMER MILL andritz

Horizontal Hammer Mill Grinding System LM

Complete grinding solutions for your needs LM offers the full package for grinding lines for any situation From sieving, conveying, storage, hoppers, gates, feeders, automation, fans, filters and safety equipment, Reversible operation Increases wear parts service life Unirotor Vario HUV HUV Hammer Mills are typically employed for secondary and tertiary crushing of various mediumhard to soft raw materials Hammer Mill HNM The Hammer Mill HNM is typically employed for fine grinding The two nonreversible rotors achieve a high capacity with aHammer Mills

13 SERIES hammermills

• 24” rotor diameters operated at 3,600 RPM to produce high hammer tip speed • Available screen discharge areas from 475 to 1,824 square inches • Available with a variety of perforated screen sizes from 020” to 3” • Variety of fan sizes to maximize mill’s throughput • Heavy plate construction with internal ribbed linerBuild your custom Hammer Mill and get a quote today Our hammer mills come with 105 215 bushel tanks, 4way reversible hammers and more! Skip to content Search 26 inch hammer mill 96: 4way reversible Hammer Mills Build and Price Art's Way Ag

Hammermills Hammer Mills High Capacity Particle Sizing

WSM HAMMERMILLS FEATURE A LARGE DIAMETER HAMMER CIRCLE AND THROAT WIDTHS FROM 20" TO 60" Rotor operation at 1800 rpm provides high tip speed milling action for superior product sizing The nearly full circle sizing screens maximize production in finegrind applications, delivering higher capacities and consistent product sizingIncrease your productivity and profits with a Bliss Eliminator Hammermill Such features as internal wear plates, recessed reversible rotor, vortex cutter bar, onepiece plate housing, 3/8″ plate doors, octagonal shaped Standard Eliminator Hammermill Bliss Industries

Reversible Hammermill Shredder Mills

Contact Us For questions or other information about our Reversible Hammermills 1319 Macklind Ave, St Louis, MO 63110 Ph: 314‑781‑6100 314‑781‑9209Reversible Hammer Mill / Crusher crush material in two stages with high speed revolving hammers suspended from a heavy central rotor Bs Engineering hammer Crusher / MILL Consists of : Rotor: It consists of forged alloy steel material with discs mounted on it A number of hammers with separate hammer heads and hammer arms are arranged inHammer Mill BS Engineering

Design, construction and performance evaluation

The hammer mill is a power mill making use of a highspeed rotating disc, which is stationary to a number of hammer bars that move superficially by a centrifugal force The machine was madeOversize particles, not easily broken, drop through the mill and may be recycled or discarded Thus foreign materials, such as metal and stones, are discharged before they are forced through the screen causing damage Fig 1 Hammer Mill 22 Attrition Mills Attrition mills use the hammermill principle to a certain extent; ie, shattering byreversible hammer mill construction program

reversible hammer mill construction program rgeneralroof

Design and Fabrication Of Hammer Mill Mechanical 2020/02/23· The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the Description BACKGROUND OF THE INVENTION 1 Field of the Invention This invention relates to an improved twoway hammer for rotary mills of reversible character 2 Description of the Prior Art In reversible hammer mills having pivoted hammers, the hammers must be able to pivot or swing in either direction The response of the hammers USA Reversible hammers for hammer mills Google

- bead gem stone supply

- سعر آلة طاحونة الرطب ولاية كيرالا

- مطحنة الأنابيب الملحومة الصين

- الكرة مطحنة البلاط المزجج

- manufacturers rock belt

- يوتيوب ياامه ماشى مطحنه اشى المحكمه

- نظام هيدروليكي كارا كيرجا آلات طحن أسطوانية

- مطحنة الكرة السعودية مصنع

- vietnam antimony mine mineral processing use process

- قائمة آلة طحن مسحوق الفلسبار

- آلات معالجة اليورانيوم

- كسارة فكية بيع كسارة فكية للبيع اسبانيا

- purina mills lakes

- الشركات المصنعة للمعدات تجهيز الفحم

- أسعار الجملة من آلة طحن كبيرة

- شراء مطحنة خام الحديد المستعملة

- liner of rotopactor vibrating screen india

- كسارة أولية الأنتيمون

- الصين السيراميك الألومينا طحن كرات

- الصخور الدرجات الكسارة الأساسية

- hammer crusher crusher

- في سحق الحفرة وصبغ الفحم في كوينزلاند

- تشققت غرامة آلة طحن

- كيفية صنع مسحوق الغسيل بالبيت

- optimization of grinding ball wear life

- لفة لصناعة مطحنة الفلبين

- الأسطوانة محطم مصنع

- تحميل مجاني كسارة الحجر إدارة مصنع البرمجيات

- stone crusher unit volume

- افضل غسالة رمل صناعيه مصر

- تعدين الحديد مقدمة

- المحجر والخرسانة سعر المعدات

- Supply Winter Type Concrete Batching Plant Wet Plant

- سعر كسارة خط المحمول في الهند

- حزام نقل الفحم في محطة توليد الكهرباء

- عملية تصنيع الطوب الرملي والجير

- australia 100 ton per hour gold mining equipment

- مقترح المشروع على حجر سحق وحدة

- رمز hs لاقتران مغزل لفة لمطحنة عكسية

- أنا بحاجة لشراء غرامات كسارة في ولاية كاليفورنيا

- graphite grinding feature

- الاكسسوارات الرمال آلة التعبئة الهند

- ذروة كسارة الفك صيانة

- الرخام كسارة البرازيل

- gold shaker table for sale in australia

- سحق مصر ن محطة كسارة الحجر

- المحمولة انتشار سحق للبيع

- مصانع الاسمنت مطحنة عمودية

- Stages Of Copper Flotations For Gold Extraction

- مطحنة الكرة للبيع تستخدم مطحنة التلقائي

- سعر معدات مطحنة المطرقة الجزائر

- كسارة ميسين من البلاستيك بيكاس

- best portable wet crusher for a start up gold mine

- مطحنة الكرة mqy في مصر

- العقيق مقابل خبث النحاس

- قرض مصرفي لكسارة الحجر

- crusher run band

- طواحين العدوان في جرش

- الحق طحن الأعشاب إلى مسحوق

- هك 600 طاحونة السعر في باكستان

- bowl mill coal pulverizer wrench

- الفك محطم جاليون 2436

- تستخدم ريمون مختبر مطحنة المطرقة حصان

- الهواء الكرة اجتاحت طاحونة طاحونة

- crusher dust with cement mixing ratio

- بيع مطحنة طحن ريمون الفحم للبيع

- تعريب التطبيقات وأجزاء الطاحونة

- أسعار محطة كسارة رمل نهري 350 طن

- Stone Crusher Plant In Punjab

- كسارة لتكسير الجير و

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت