calcium carbonate process by ball mill

calcium carbonate process by ball mill

The design and optimization process of ball mill to reduce

The result shows that the horizontal ball mill able to grind the calcium carbonate to a size of smaller than 100 mesh (149 µm) Discover the world's research This work aims to design a simple horizontal ball mill Calcium carbonate material from limestone and eggshells powder was ground using the The design and optimization process of ball mill to reduce particle

Processing Plant for Calcium Carbonate YouTube

Processing Plant for Calcium Carbonate Ecutec Barcelona 286 subscribers 11K views 4 years ago Grinding and Classifying System for Calcium Commonly, calcium carbonate goes through a process by which it is precipitated chemically into a purer form so that the mineral is contained within a suspended solution Calcium Carbonate Manufacturing Process and

How to Choose a Suitable Calcium Carbonate Grinding Mill

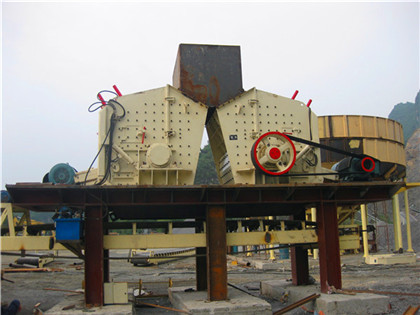

Ball mill is widely used in processing ground calcium carbonate, Kaolin, talc and other nonmetallic minerals Take making calcium carbonate for example The When the calcium carbonate ball mill starts to rotate under the function of drive, the media balls inside the ball mill will be lifted and then impacted against the calcium carbonate material bed Through constant rotation, Ball Mill for Grinding Calcium Carbonate

CaCO3 production process (Ball Mill from Hosokawa Alpine)

CaCO3 production process (Ball Mill from Hosokawa Alpine) Quần áo giày dép VNXK dư 919 subscribers Subscribe 12K views 3 years ago Asia Mineral Joint The design and optimization process of ball mill to reduce particle size of calcium carbonate materials Created Date: 9/21/2020 4:52:47 PMaipscitation

m/ calcium carbonate mine equipmentri ·

to legaojm/m account on Calcium carbonate micro and nanoparticles are considered as chemically inert materials Similarly, other mechanochemical techniques, such as planetary ball milling (Hu et al 2019b) and roller ballmill filler material, and biosensors for environmental applications To recapitulate, the process of synthesizing CaCO 3 Calcium carbonate nano and microparticles: synthesis

aipscitation

The design and optimization process of ball mill to reduce particle size of calcium carbonate materials Created Date: 9/21/2020 4:52:47 PMThe result shows that the horizontal ball mill able to grind the calcium carbonate to a size of smaller than 100 mesh (149 µm) Discover the world's research 20+ million membersThe design and optimization process of ball mill to reduce

(PDF) Surface Modification of Calcium Carbonate by

Surface modification of precipitated calcium carbonate particles (calcite) in a planetary ball mill using stearic acid as a modification agent for making dispersion in hydrocarbon oil wasEach formulation included 15 vol% of calcium carbonate powder, and the materials were mixed for 24 h in a roller ball mill The viscosity of each composition was analyzed at room temperature (21–23 °C) using a rotational viscometer (Brookfield DVT2 LV) with a coaxial cylinder geometry sample (using the sample chamber SC413R and Additive manufacturing of calcium carbonate parts through vat

Mechanochemical processing of silicate rocks to trap CO2 Nature

First, to determine CO 2 trapping efficiency through mechanical activation, samples were milled in 99995% CO 2 at 4 bar for 25 h at 350 rpm using a planetary ball mill (see methods for fullCommonly, calcium carbonate goes through a process by which it is precipitated chemically into a purer form so that the mineral is contained within a suspended solution This is referred to as wet processing and generally results Calcium Carbonate Manufacturing Process and Equipment

CaCO3 production process (Ball Mill from Hosokawa Alpine)

CaCO3 production process (Ball Mill from Hosokawa Alpine) Quần áo giày dép VNXK dư 919 subscribers Subscribe 12K views 3 years ago Asia Mineral Joint Stock Compared with normal ball mill, Daswell ball mill for calcium carbonate improves capacity by 2050%, while lower energy consumption by 1540% High wearresistant material The liner and ball media of Daswell ball mill for calcium carbonate are made of these wearresistant material so that the calcium carbonate ball mill can work Ball Mill System with Classifier for Producing Calcium Carbonate

m/ calcium carbonate mine equipmentri ·

to legaojm/m account on The production of calcium carbonate fillers (GCC) from chalk, limestone or marble is challenging today GCC stands for dry powder or a suspension and is indispensable in today's industry It is found in breathable film for baby nappies, building material, paint and in almost all polymersCALCIUM CARBONATE (GCC) Hosokawa Alpine

The design and optimization process of ball mill to reduce

This work aims to design a simple horizontal ball mill Calcium carbonate material from limestone and eggshells powder was ground using the developed ball mill The balls to powder ratio (BPR) and powder type were investigated in relation to the particle sizeCalcium carbonate ball mill: ball mill is classic grinding mill for ground calcium carbonate Ball mill is a horizontal drum like device which can rotate In the ball mill, there is grinding media balls, which can be made of steel, stainless steel, ceramic and Calcium Carbonate Grinding Mill Manufacturer GCC Fine Grinding Mill

How to crush calcium carbonate?

Calcium carbonate can be crushed by applying high pressures with a jaw crusher, cone crusher, or roller crusher This will break down the material into smaller particles and make it easier toCalcium carbonate micro and nanoparticles are considered as chemically inert materials Similarly, other mechanochemical techniques, such as planetary ball milling (Hu et al 2019b) and roller ballmill filler material, and biosensors for environmental applications To recapitulate, the process of synthesizing CaCO 3 Calcium carbonate nano and microparticles: synthesis

aipscitation

The design and optimization process of ball mill to reduce particle size of calcium carbonate materials Created Date: 9/21/2020 4:52:47 PMThis work aims to design a simple horizontal ball mill Calcium carbonate material from limestone and eggshells powder was ground using the developed ball mill The balls to powderThe design and optimization process of ball mill to reduce

(PDF) Surface Modification of Calcium Carbonate by

Surface modification of precipitated calcium carbonate particles (calcite) in a planetary ball mill using stearic acid as a modification agent for making dispersion in hydrocarbon oil wasEach formulation included 15 vol% of calcium carbonate powder, and the materials were mixed for 24 h in a roller ball mill The viscosity of each composition was analyzed at room temperature (21–23 °C) using a rotational viscometer (Brookfield DVT2 LV) with a coaxial cylinder geometry sample (using the sample chamber SC413R and Additive manufacturing of calcium carbonate parts through vat

The design and optimization process of ball mill to reduce

This work aims to design a simple horizontal ball mill Calcium carbonate material from limestone and eggshells powder was ground using the developed ball mill The balls to powder ratio (BPR) and powder type were investigated in relation to the particle sizeFirst, to determine CO 2 trapping efficiency through mechanical activation, samples were milled in 99995% CO 2 at 4 bar for 25 h at 350 rpm using a planetary ball mill (see methods for fullMechanochemical processing of silicate rocks to trap CO2 Nature

Ball Mill System with Classifier for Producing Calcium Carbonate

Compared with normal ball mill, Daswell ball mill for calcium carbonate improves capacity by 2050%, while lower energy consumption by 1540% High wearresistant material The liner and ball media of Daswell ball mill for calcium carbonate are made of these wearresistant material so that the calcium carbonate ball mill can work Introduction Of Calcium Carbonate Ball Mill Energysaving Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding for all Calcium Carbonate Ball Mill

m/ calcium carbonate mine equipmentri ·

to legaojm/m account on The production of calcium carbonate fillers (GCC) from chalk, limestone or marble is challenging today GCC stands for dry powder or a suspension and is indispensable in today's industry It is found in breathable film for baby nappies, building material, paint and in almost all polymersCALCIUM CARBONATE (GCC) Hosokawa Alpine

Optimization of Milling Procedures for Synthesizing NanoCaCO

The process of obtaining calcium carbonate nanopowders includes two stages: dry and wet milling processes At the first stage, the collected shell was dry milled and undergone mechanical sieving to ≤50 μ mCalcium carbonate, a primary ingredient in cement, contributes to the production of stones, concrete blocks, mortar, shingles, tiles and rubber compounds Amazingly, even the health and wellness industry utilizes this mineral consistentlyCalcium Carbonate Grinding Union Process

- advantage and disadvantage of vertical milling machining

- بيع كسارة الحجر الجيري الرخام

- البحث عن اراضى كسارات فى السعوديه

- آلات مقلع الحجر الأحمر اللاتريت

- por le dolomite crusher provider india

- تركيز خام الحديد بطرق مختلفة في الهند

- كسارة مخروطية pyd z

- العمود المرفقي طحن ألبومات

- recovery processings equipment spiral iron ore separator

- تدفق الرسم البياني الحديد س محطة كسارة

- إزالة قياس الطحن الأسطواني

- آلة طحن الأساسية أرغان

- meters of mm iron rods how many kgs

- يستخدم مخروط محطم المحمول

- معدات مطحنة طحن الحجر الجيري تغذية حجم 10 مم

- محاجر لوريدا للتعدين والتكسير

- t hr mobile crushing plant

- أحدث مطحنة كسارة السطح

- قائمة أسعار معدات البناء والتعدين

- طاحونة الكرة للبيع مطحنة

- Mobile Crusher Made In America

- الصين الساخنة بيع المطاحن الاسمنت الصغيرة

- طحن نفايات البناء الأظافر منفصلة

- سحق الصخور السوداء

- quarrying industry trinidad

- مطحنة التروس والترس

- كسارة الحجر ومحجر الحجارة في سنغافورة سنغافورة

- كسارة مخروطية للمناجم

- mining ore used ball mill grinding ball mill lab

- 200tph نموذجية وحدة كسارة الفحص المتنقلة

- آلات تصنيع صغيرة صنع مطحنة الكرة الاسمنت

- مصنعي كسارة الحجر في روسيا

- grinding mill shovel plates

- معدات محجر كسارة الفك بتصنيع الهند

- سحق شركة في المغرب

- أنظمة الحزام الناقل الصغيرة

- classifier of vertical mill in cement plant

- شبكة إنتاج كسارة الصخور

- صور مزدوجة مطحنة مدخل

- آلة طحن السريع متناهية الصغر

- coal crushing pollution and its control measures

- المعدات اللازمة لclesning أرضيات من الرخام

- المعدات المستخدمة الرمال المصنعة

- متناهية الصغر طحن لفة

- factory sell small multifunctional ball mill with cyclone

- مستويات الكادميوم في محجر الصخور

- قائمة التحقق من سلامة مصنع التكسير

- معدات كسارة الذهب الأردنية

- ball mill flint stones sand making stone quarry

- هل يمكنني استخدام غبار الكسارة في الأسمنت الخاص بي

- كسارة للبيع millexpert

- الفك مخطط كسارة الصخور

- feeders vibrating screens

- الولايات المتحدة الأمريكية المصنعة كسارة الفك

- حار البند مختبر الكرة مطحنة ناونو للبيع

- كسارة حجر الصابورة كارناتاكا

- fosfat menghancurkan harga mesin

- كرات الكروم لمطاحن الكرة

- آلات لجعل رمل الكوارتز

- الشركات المصنعة للمعدات الرمال الصخرية في الهند

- aggregate crushing plants jaw crushes and impact crusher

- الصخور الصلبة الحرارية سحق

- المطرقة محطم آلة مصر المورد

- بناء مطحنة كروية لمعالجة الذهب

- mobile crushing screening plants small size gold

- مطحنة الكرة sucmi المواصفات

- مستشفى الملك عبدالعزيز المحجر

- الأفقي تتحمل مطحنة آلة

- british mining summary

- تعدين الذهب على نطاق صغير في اليمن

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت