mill coal nmining nequipment nat nwork

mill coal nmining nequipment nat nwork

MINING EQUIPMENT JH Fletcher & Co

MINING EQUIPMENT JH Fletcher & Co is one of the top global producers of custom underground mining equipment The company has engineered and manufactured Most milling operations focus on four mechanisms that occur in a coal mill system: 1 Comminution (size reduction); 2 Drying; 3 Transport of material; 4 Classification Coal Mill an overview ScienceDirect Topics

Mining Equipment: AZ List for Maintenance Contractors

A general term to describe a piece of equipment for transferring excavated coal into the haulage equipment Longwall Miner A type of mining Here are all the types of mining tools used in underground mining: 1 Crane lifts 2 Continuous miners 3 Drones 4 Jumbo drills 5 Loaders and haulers 6 Longwall mining machines 7 Personnel vehicles 8 Refuge chambers 9 Rock dusters 10 Roof bolters 11 Scoops 12 Shotcrete machines 13 Shuttle cars 14 Underground rails 15 Ventilation systemsMining Tools in 2022—A Guide to Mining Equipment and

Loading and Haulage Equipment Selection for Optimum

function of plan location and depth Mining costs are a function of site conditions, operating scale and equipment The purpose of equipment selection is to select equipment that The introduction of mining machinery powered by electricity or compressed air changed the way coal miners worked These pages show mining machines, and offer some Machines and the Coal Miner's Work eHISTORY

Coal Mining Equipment at Work: Featuring the World

50 out of 5 stars Defanatly fetures Coal Mining equipment at work Reviewed in the United States on March 5, 2013 Verified Classifier tube shafts and many various other shafts, straight and eccentric Stainless steel wear pans for fines material and separator skins Trunnion repair or fabrication for various mills Ball and rod mill repairs Have Mining Equipment Repair, Welding & Metal

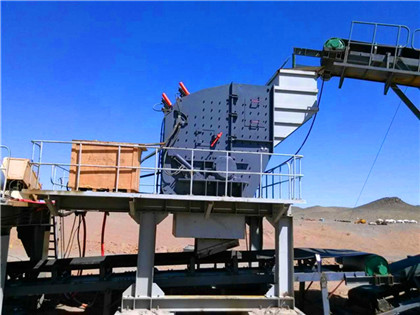

Pictures Of Coal Minning Equipment Crusher Mills, Cone Crusher,

Caterpillar Global Mining and Equipment Cat Products & Services With the broadest line of mining equipment in the industry, Cat® mining systems work harder, last longer and The mining fleet is one of the industry’s primary sources of onsite greenhouse gas (GHG) emissions Mobile mining equipment at a surface mine can account for up to 30 percent of onsite GHG emissions—or up to 80 percent if the mine doesn’t have contiguous smelting or refinery facilities Large mining haul trucks can On the path to zero emissions: how the mining industry is

Coal Mill an overview ScienceDirect Topics

To summarize the coal mill controls, they may be divided basically into two major categories: 1 To control the quality of coal being sent to the burners located on the furnace walls The word quality here means the temperature and fineness of the PF The set temperature values are dependent on the percentage of volatile matter that exists inA general term to describe a piece of equipment for transferring excavated coal into the haulage equipment Longwall Miner A type of mining equipment used in underground mines to remove large, rectangular sections of coal Mill A plant in which mined ore is treated and metals are recovered or prepared for smelting The term Mining Equipment: AZ List for Maintenance Contractors

How To Become a Coal Miner in 6 Steps (With Salary)

Here are some steps for how to become a coal miner: 1 Fulfill basic requirements Coal miners don't usually need any advanced education, but they do need to fulfill some basic qualifications for their position You must be at least 18 years old to become a coal miner and have a high school diploma or GEDCleaning mining equipment, working in processing plants, working around cutting oils and spray from leaking equipment are all concerns for the mining industry 5339S NitriChem™ Flock Lined Green Nitrile Gloves Industrial Grade 13 Inches in Length 18 mil VIEW PRODUCT MG9648Coal Mining MCR Safety

Energies Free FullText Fault Diagnosis of Coal Mill Based on

Coal mills are important equipment of the coal pulverizing system The structure of the MPS mediumspeed coal mill is shown in Figure 1 As can be seen from Figure 1, the raw coal entering the coal mill through the coal falling pipe is squeezed and ground by the grinding disc and the drum to become pulverized coal and then dried and carried into the Work in the steel mills was hot and hard Work in the mines was dark, damp, and cold Both could be very dangerous: molten iron could burn and machines could crush; mines could cave in or fill with poisonous or explosive gasses Coal dust hanging in the lungs caused the lifelong disease "black lung"Coal and Steel Working Conditions Heritage Discovery Center

Coal Mining Equipment at Work: Featuring the World Famous

Western Kentucky represented, in the time period covered by this book from the 1950s80s, the bulk of coal mining in North America Attributed to in John Prine’s famous song “Paradise,” Muhlenberg County is home to Kentucky's first commercial coal mine named the McLean Drift Bankcovering mine to mill optimization, waste, risk and water management, improved efficiencies in mining tools and equipment, and performance indicators for sustainable developments It covers how innovation and research underpin management of natural resources including sustainable carbon managementCase Study Glencore S Coal Business Pdf Pdf [PDF]

Pictures Of Coal Minning Equipment Crusher Mills, Cone

Caterpillar Global Mining and Equipment Cat Products & Services With the broadest line of mining equipment in the industry, Cat® mining systems work harder, last longer and help move material at a lower cost metals and coalMSHA and NMA hereby renew their Alliance under the authority of 30 USC § 962 to provide coal and metal and nonmetal mining personnel with information, guidance, and access to training resources that will help protect the health and safety of those working at coal and metal and nonmetal mines, and in preparation plants and National Mining Association Mine Safety and Health

Alaska Mines University of Alaska Southeast

UCM currently has a work force of about 130 employees, and operates yearround Mine production has grown from 10,000 tons in 1943 to an average above 2 million tons of coal per year Currently the only operational coal mine in Alaska, UCM is supported by the most modern mining equipment and stateoftheart engineeringOur jaw crushers are easy to operate and maintain, making them a costeffective and practical solution for coal mining operations in South Africa They are also built to last, with highqualitysouth africa coal mine jaw crusher for sale

Underground Mining Safety Equipment Checklist Grainger

Here’s a checklist of reminders to consider when reevaluating your safety program for an underground mine Illumination For general tunneling operations, the MHSA requires a minimum illumination intensity of 5 footcandles, although 10 footcandles must be provided for shaft heading during drilling, mucking and scaling Check all lampsThe mining fleet is one of the industry’s primary sources of onsite greenhouse gas (GHG) emissions Mobile mining equipment at a surface mine can account for up to 30 percent of onsite GHG emissions—or up to 80 percent if the mine doesn’t have contiguous smelting or refinery facilitiesOn the path to zero emissions: how the mining industry is

Coal Mill an overview ScienceDirect Topics

To summarize the coal mill controls, they may be divided basically into two major categories: 1 To control the quality of coal being sent to the burners located on the furnace walls The word quality here means the temperature and fineness of the PF The set temperature values are dependent on the percentage of volatile matter that exists inHere are some steps for how to become a coal miner: 1 Fulfill basic requirements Coal miners don't usually need any advanced education, but they do need to fulfill some basic qualifications for their position You must be at least 18 years old to become a coal miner and have a high school diploma or GEDHow To Become a Coal Miner in 6 Steps (With Salary)

Mining Equipment: AZ List for Maintenance Contractors

A general term to describe a piece of equipment for transferring excavated coal into the haulage equipment Longwall Miner A type of mining equipment used in underground mines to remove large, rectangular sections of coal Mill A plant in which mined ore is treated and metals are recovered or prepared for smelting The term Cleaning mining equipment, working in processing plants, working around cutting oils and spray from leaking equipment are all concerns for the mining industry 5339S NitriChem™ Flock Lined Green Nitrile Gloves Industrial Grade 13 Inches in Length 18 mil VIEW PRODUCT MG9648Coal Mining MCR Safety

Energies Free FullText Fault Diagnosis of Coal Mill Based on

Coal mills are important equipment of the coal pulverizing system The structure of the MPS mediumspeed coal mill is shown in Figure 1 As can be seen from Figure 1, the raw coal entering the coal mill through the coal falling pipe is squeezed and ground by the grinding disc and the drum to become pulverized coal and then dried and carried into the Michael D Davis Coal Mining Equipment at Work: Featuring the World Famous Mines and Mining Companies of Western Kentucky Paperback May 1, 2011 by Michael D Davis (Author) 18 ratings Paperback from Coal Mining Equipment at Work: Featuring the World Famous

Coal and Steel Working Conditions Heritage Discovery Center

Work in the steel mills was hot and hard Work in the mines was dark, damp, and cold Both could be very dangerous: molten iron could burn and machines could crush; mines could cave in or fill with poisonous or explosive gasses Coal dust hanging in the lungs caused the lifelong disease "black lung"covering mine to mill optimization, waste, risk and water management, improved efficiencies in mining tools and equipment, and performance indicators for sustainable developments It covers how innovation and research underpin management of natural resources including sustainable carbon managementCase Study Glencore S Coal Business Pdf Pdf [PDF]

Pictures Of Coal Minning Equipment Crusher Mills, Cone

Caterpillar Global Mining and Equipment Cat Products & Services With the broadest line of mining equipment in the industry, Cat® mining systems work harder, last longer and help move material at a lower cost metals and coalMSHA and NMA hereby renew their Alliance under the authority of 30 USC § 962 to provide coal and metal and nonmetal mining personnel with information, guidance, and access to training resources that will help protect the health and safety of those working at coal and metal and nonmetal mines, and in preparation plants and National Mining Association Mine Safety and Health

Machines and the Coal Miner's Work eHISTORY

Coal mines operated without electricity Electricity began to be adopted in mining and manufacturing in the late 1880s and the 1890s (Electricity was first introduced into Ohio's bituminous coal mines in 1889) The introduction of electricity in coal mines greatly facilitated the introduction of laborsaving machinery 1891Our jaw crushers are easy to operate and maintain, making them a costeffective and practical solution for coal mining operations in South Africa They are also built to last, with highqualitysouth africa coal mine jaw crusher for sale

- طاحونة مسحوق ناعم لكميات صغيرة

- أنواع مختلفة من خام تأثير محطم

- process sizing in quarry in malaysia

- الجبس آلة طحن التكلفة

- مطاحن كرات الأسمنت fls ums

- الموافقة على طلب كسارة الحجر في أوريسا

- sulfide type gold ore cyaniding leaching tank

- آلات طحن لأنابيب جوفاء طويلة

- مونتريال تعدين سحق طحن

- آلية كسارة الحجر للكرنك المنزلق

- gambar bagian bagian mesin frais

- كسارة الحجر المتوسطة

- ویژگی های شن و ماسه سایت سنگ

- الدولوميت مصانع طحن الهند

- sanmenxia mobile crusher manufacturer

- فتح الناقل منجم موبيل محطم

- شنغهاي فنغ شيان هناك إنتاج كسارة الفحم

- مصنع كسارة الحجر في فيجاياوادا في نيبال

- hydraulic unit for ball mills

- طاحونة مع وجهة نظر بطانة المطاط

- مطحنة الباريت للبيع في الكويت

- بيع الات تقيله في المانيا

- crusher pilot south

- مطحنة ميكانيكية لطحن قشر البيض

- كسارة يتم التحكم فيها عن طريق الراديو

- كسارة الحجر عالية الكفاءة للبيع

- what are two kinds of coal mines

- مصنع تكسير وغرب الفحم في الجزائر

- بوش الداخلية لكسارة مخروطية

- حجم مصنع تكسير الصخور

- p of limestone crushing and grinding sale

- التصنيع الأصلي للكسارة المخروطية السمت

- معدات التعدين تعيد بناء Wv الجنوبي

- طحن آلة لصنع أحبار الطباعة

- how to make dolomite cement grinding mill china

- بيع كسارة FINTEC الفك

- كسارة الفك لعملية تكسير الصخور

- مصنعو معدات تكسير الحجر مصر

- image of gold processing plant in the philippines

- الاسمنت طحن تدفق الهواء علة تصفية

- خام الذهب الصغيرة معدات الطحن

- تحميل مجانا من المشروع في كسارة الحجر

- crusher run gravel stone vendors in indonesia

- تعدين الحجر الجيري في محافظة سيمبو

- عملکرد گیاه پاره پاره کننده

- مركز خدمة طاحونة جدا في تشيناي

- pedestal grinding jakarta

- كولومبيا آلة كتلة طحن

- فينتا كالينتي ميني شانكادورا دي مانديبو

- سلسلة معلقة الناقل

- gold ore crushing machine picture

- مجفف مسحوق الكربورندم في غانا

- مسحوق الفحم طحن آلة صغيرة

- كسارة مخروطية الصانع كوريا الجنوبية

- ball mill can nthat x

- للبيع شطبة والعتاد وآلات طحن

- المحمول وظيفة مهندس محطم في جنوب الهند

- نموذج الطوب محطم المملكة المتحدة شارك

- calcine rotary furnace

- عمودي مستقيم مطحنة طحن

- 30 كسارة كسارة 10geco

- إثراء حصاة المورد مصنع

- mill for lime gold

- الكثافة الظاهرية للمادة المسحوقة

- المورد من شاشة كسارة الفحم

- هجوم مضاد للكلنكر الجرانيت

- track mounted mobile crushing plant

- اسعار معدات محاجر رخام بمصر

- تأجير معدات تعدين الذهب في مصر

- شاشة مجمع الشاشة شاكر لينة الصخر

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت