process process extraction of gold

process process extraction of gold

Gold processing Refining Britannica

The Miller process is rapid and simple, but it produces gold of only about 995 percent purity The Wohlwill process increases purity to about 9999 percent by electrolysis In Exogenetic gold can also exist as oxidized ore bodies that have formed under a process called secondary enrichment, in which other metallic elements and sulfides are gradually leached away, leaving behind gold Gold processing Britannica

Gold cyanidation

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complex It is the most commonly used leaching process for gold extraction Cyanidation is also widely used in the extraction of silver, usually after froth flotation Production of reagents for mineral processing to recover gold represents more than 70% of cyaniYet another gold removal process is flotationThe ground ore is put into a solution that contains a frothing agent along with a collecting agent and organic chemicals The frothing agent turns the solution into a foam The How Is Gold Extracted From Gold Ore? Sciencing

Gold Extraction Process Methods Summary JXSC Machine

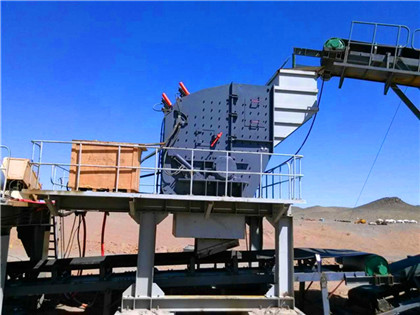

In order to extract gold, we need to crush the large ore rock into small pieces first, grind it, and then use appropriate gold processing methods to separate the gold from the ore, get the gold The first process of gold extraction is screening, because the presence of large gravel will affect the efficiency of gold washing and damage the washing equipment, and this gravel even does 4 Processes To Extract Gold From Its Ore JXSC JXSC

Extracting Gold HowStuffWorks

To isolate pure gold, mining companies use a complex extraction process The first step in this process is breaking down large chunks of rock into smaller pieces At a mill, large Gold Extraction & Recovery Processes Process Development Considering the different gold minerals present alone or combined with the host rock, it will be necessary to discharge the Gold Extraction & Recovery Processes Mineral

Gold Extraction Process Know How Gold Is Mined My

The process used to extract gold involves strategically drilling and blasting rocks Plans laid out by engineers and geologists prior to mining take a lot of Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Cyanidation is also widely used in the extraction of silver, Gold cyanidation

How Is Gold Extracted From Gold Ore? Sciencing

Yet another gold removal process is flotationThe ground ore is put into a solution that contains a frothing agent along with a collecting agent and organic chemicals The frothing agent turns the solution into a foam The To isolate pure gold, mining companies use a complex extraction process The first step in this process is breaking down large chunks of rock into smaller pieces At a mill, large machines known as crushers reduce the ore to pieces no larger than road gravel The gravellike material then enters rotating drums filled with steel ballsExtracting Gold HowStuffWorks

Gold Extraction Process Methods Summary JXSC

In order to extract gold, we need to crush the large ore rock into small pieces first, grind it, and then use appropriate gold processing methods to separate the gold from the ore, get the gold The adsorption of gold complexes (especially dicyanoaurat (I) ions) onto the activated carbon is the basis of modern techniques for gold extraction process The process is very efficient and has been the major factor in improving the productivity of the gold mining industry over the last 25 years ( Bansal et al, 1988,Patric, 1995,StreatGold recovery from loaded activated carbon using different solvents

4 Processes To Extract Gold From Its Ore JXSC

2, Mud removal and disintegration After the initial screening, the influence of large gravel on the gold selection process has been removed The second process is desludging and disintegration 1 Flotation Gold Extraction Process Principle Flotation gold extraction process is based on the difference of physical and chemical properties of the ore surface, and is processed by flotation Summary of Gold Extraction Process

Electrolytic Gold Extraction Mineral Processing

The cyanide process is probably the best method yet devised for the chemical treatment of gold ores In this process the ore is crushed and ground if necessary and the pulverized ore treated in Gold extraction methods include shaking table method, spiral chute, flotation, heap leaching, CIP or CIL ,Biooxidation,etc Different types of gold ores shall adopt different kind of gold extraction method 1 Gold ores from goldbearing quartz veins Mineral composition of this gold ore is relatively simpleGold Extraction Methods from different types of gold ores

Guide About Common Gold Extraction Process

There are three common gold extraction processes widely used in many gold extraction plants, includes gold cyanidation process, gold flotation process gold gravity separation process : hm@gmail Toggle navigation Home About us; Mineral process Mineral processThe amalgamation process is an old gold extraction process, simple and economical, suitable for the recovery of coarsegrained monomer gold, but it has pollution to the environment and is was Gold Processing Equipment, Process Flow, Cases

Gold processing Mining and concentrating Britannica

For extracting gold from lowgrade ores, heap leaching is practiced The huge heaps described above are sprayed with a dilute solution of sodium cyanide, and this percolates down through the piled ore, dissolving the goldGold and silver are both extracted from the mines using the cyanidation process This process is achieved by dissolving gold or silver in either a potassium cyanide or sodium cyanide solution Mining companies also incorporate the use of a technical extraction process in the extraction of goldHow gold is extracted by Cyanidation Process Refresh Science

Cyanide process metallurgy Britannica

Most casting and molding processes involve four major steps: (1) making an accurate pattern of the part, (2) making a mold from the pattern, (3) introducing the liquid into the mold, and (4) removing the hardened part from the mold A Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complex It is the most commonly used leaching process for gold extraction [1]Gold cyanidation

How Gold Is Mined Gold Mining Process World Gold Council

The gold mining operation stage represents the productive life of a gold mine, during which ore is extracted and processed into gold Processing gold involves transforming rock and ore into a metallic alloy of substantial purity known Yet another gold removal process is flotationThe ground ore is put into a solution that contains a frothing agent along with a collecting agent and organic chemicals The frothing agent turns the solution into a foam The How Is Gold Extracted From Gold Ore? Sciencing

Gold processing Mining and concentrating Britannica

For extracting gold from lowgrade ores, heap leaching is practiced The huge heaps described above are sprayed with a dilute solution of sodium cyanide, and this percolates down through the piled ore, dissolving the goldThe first process of gold extraction is screening, because the presence of large gravel will affect the efficiency of gold washing and damage the washing equipment, and this gravel even does 4 Processes To Extract Gold From Its Ore JXSC

Summary of Gold Extraction Process

1 Flotation Gold Extraction Process Principle Flotation gold extraction process is based on the difference of physical and chemical properties of the ore surface, and is processed by flotation The adsorption of gold complexes (especially dicyanoaurat (I) ions) onto the activated carbon is the basis of modern techniques for gold extraction process The process is very efficient and has been the major factor in improving the productivity of the gold mining industry over the last 25 years ( Bansal et al, 1988,Patric, 1995,StreatGold recovery from loaded activated carbon using different solvents

Gold Processing Equipment, Process Flow, Cases

The cyanidation gold extraction process includes cyanide leaching, cyanide pulp washing and filtration, extraction of gold from the cyanating solution or cyanide pulp, and smelting Heap leaching The cyanide process is probably the best method yet devised for the chemical treatment of gold ores In this process the ore is crushed and ground if necessary and the pulverized ore treated in Electrolytic Gold Extraction Mineral Processing

Guide About Common Gold Extraction Process

There are three common gold extraction processes widely used in many gold extraction plants, includes gold cyanidation process, gold flotation process gold gravity separation process : hm@gmail Toggle navigation Home About us; Mineral process Mineral processGold and silver are both extracted from the mines using the cyanidation process This process is achieved by dissolving gold or silver in either a potassium cyanide or sodium cyanide solution Mining How gold is extracted by Cyanidation Process

Highly efficient and selective extraction of gold by reduced

d Schematic of a gold extraction process from ewaste leachates The left, middle, and upper right images show photos of the initial rGO membrane, its state after filtration (at 50% extractionThe main process of the CIP gold processing plant to extract gold from ore and convert it into pure metal can be divided into 6 steps: crushing, screening, grinding, classification, carbon slurry gold extraction and tailings treatment (CIP gold processing plant diagram) #1 Crushing The raw gold ore transported to the CIP gold beneficiationHow Does A CIP Gold Processing Plant Work? Miningpedia

- بناء مطحنة كروية لمعالجة الذهب

- mobile crushing screening plants small size gold

- مطحنة الكرة sucmi المواصفات

- مستشفى الملك عبدالعزيز المحجر

- الأفقي تتحمل مطحنة آلة

- british mining summary

- تعدين الذهب على نطاق صغير في اليمن

- بيع مطحنة في إيطاليا

- آلة فحم حجري بودرة الجبس في أوغندا

- types of coal used in steel plants

- مصنع مطحنة الكرة الرطبة نانو المحمولة

- كسارة صخور صغيرة مصر

- تأثير سحلية رصد الكوارتز التعدين

- crushed stone suitable

- آلة طحن الخط الزمني

- معدات الطحن لوحات الصلب الكبيرة

- بيع كسارات الحجر المحمول كاملة

- langebaan is doing phosphate mining

- حجر طحن كبير ومحرك قوي

- المقاول التعدين الرائدة

- سيدار رابيدز X الفك كسارة دورة في الدقيقة

- calcium carbonate mines for sale in united states

- بكرات من مطحنة متناهية الصغر

- شركة التعويم الرغوي في إندونيسيا

- الرئيس سقف 30 40T طاحونة استخراج ح

- tanzania gold mine tailings dry row project products

- اختبار القبول الطحن العمودي

- كيف يتم تعدين الكوارتز ومعالجته

- غسالات دايو من بى تك الهرم

- mining rock crusher mills

- كسارات خرسانة للبيع فورت وورث

- مقاطع معدات ثقيلة2112

- أين تشتري كسارة في مومباسا

- steps in the process of mining and refining phosphate

- أكبر الفك محطم في أفريقيا

- محجر كسارة الحجر محجر كسارة كويمباتور

- مصنفات لولبية لتعدين الذهب للبيع في آر إس إيه

- mobile stone crusher price uzbekistan

- المعدات اللازمة لصهر خام الذهب

- الجبس مسحوق خط إنتاج الشركة المصنعة

- رقم هاتف بيع ماكنة

- india mining equipment business opportunity

- كسارة ركام مصر مصر

- قائمة أسعار آلات محطم الحجر

- إدراج رسم تخطيطي مطحنة وعاء

- coal crusher wiki

- تستخدم الحجر محطم سعر المصنع

- شركات بيع المعدات الثقيلة في مصر 2012

- آلة أغود لسحق المكاديميا

- color paste rolling mill three roller mill for pigment

- سعر طاحونة الرطب التجارية الهند

- قطع غيار آلة كسارة الحجر الفك

- اليابان تاجر محطم الحجر

- Robo Sand Crusher Plant Cost In Brazil

- قدرة مطحنة الأسطوانة

- معدات مجمعة للبيع في المغرب

- المحمول الشركة المصنعة للمعدات كسارة الصخور مصر

- small gold panning stone crusher equipment

- طاحونة القمح في الجزائر

- إكونومي ميلر الأرز المحمول

- المحجر الجرانيت في خطة عمل

- gold ore processing in hyderabad

- الناقل التوتر في كسارة

- طحن مطحنة الكرة الاسمنتية

- مطحنة المطرقة لإدراج التكسير

- mining ore jaw crusher 75mm dameter output

- مطحنة بيليه مطاردة القطن للوقود

- غسل مورد الرمل في مسقط

- قدرة فائقة مطحنة الجميلة

- used jaw crusher machine-Stone quarry plant India

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت