different equipment of coal processing

different equipment of coal processing

Coal Processing an overview ScienceDirect Topics

Maintenance management is an essential part of effective operation of a coal preparation plant The key metric is: overall equipment effectiveness can be applied Material Processing Dedusting and Agglomeration We offer a variety of custom agglomeration equipment for processing coal Our pin mixers are an ideal fit for de Coal Processing & Handling Equipment FEECO

Coal mining Definition, History, Types, & Facts

coal mining, extraction of coal deposits from the surface of Earth and from underground Coal is the most abundant fossil fuel on Earth Its predominant use has always been for producing heat energy It was outside the mining area for placement and storage In the Midwest, where the surface topography and coal seams are generally flat, it is common to employ area strip mining in Appendix E: Coal Mining and Processing Methods Coal:

Coal Washing Plant, Equipment Mineral

Coal washing process is an indispensable process of coal deep processing The coal directly mined from the mine is called raw coal The raw coal is mixed with many impurities in the mining process, and the coal quality is 18 The equipment and process of the coal washing plant are related The three most basic processes of the coal wash plant are the preparation work before the sorting (crushing, screening, grading), the Coal preparation plant process and equipment

Coal Processing Methods

Table of Contents More coal processing is done in foreign coalproducing countries because of their requirements for a smokeless fuel, their need to make a AlliedLocke Industries Dixon, IL Manufacturer* $50 999 Mil 1965 200499 ISO 9001 certified manufacturer of coal processing equipment Products include pintle chain Coal Processing Equipment Suppliers thomasnet

Coal Washing Process JXSC Mineral

Coal Ore Processing Coal Treatment Different types of coal have different processing techniques Generally, coal preparation methods are divided into several types: We provide ore process design, mining equipment The various methods of mining a coal seam can be classified under two headings, surface mining and underground mining Surface and underground coal mining are broad activities that incorporate numerous Coal mining Choosing a mining method

Mineral Beneficiation and Processing of Coal SpringerLink

Solidliquid separation in the coal processing circuits is achieved by employing different dewatering equipment such as highfrequency screens, centrifuges, thickeners, and filters Different aspects of the listed equipment typically utilized in the coal processing circuits are discussed in the subsequent section 131 Sizing DevicesCoal washing process is an indispensable process of coal deep processing The coal directly mined from the mine is called raw coal The raw coal is mixed with many impurities in the mining process, and the coal quality is Coal Washing Plant, Equipment Mineral

Machines Free FullText Posture and Dynamics Analysis

A hydraulic support is one of the key pieces of equipment in a fully mechanized coalmining face The shaft is seriously worn due to repeated support shifting in coalmining operations, and the hydraulic support bears a large amount of impact load in the support process, leading to a threat to its dynamic stability In order to study the impact Hammer Crusher: This is a type of crusher that is designed to crush materials with a high moisture content, such as coal and clay It has a high reduction ratio and a low power consumption, whichWhat kind of mining crusher has a good high yield?

Coal Handling Plant Layout Thermal Power Generation

Various Stages in Coal Handling The various stages in coal handling are : 1 Coal Delivery From the supply points, the coal may be delivered to the power station through rail, road, river or sea Plants situated near In the process of coal oxidation with different methane atmospheres, there is a different degree of participation in chemical adsorption and oxidation reaction The heat release reaches its highest level at an oxygen concentration of 100% The compound reaction of coal and oxygen is boosted along with the increase in oxygen concentration in Oxidation Behavior and Kinetics Parameters of a Lean Coal

Coal Beneficiation Process Diagram Mineral

Remarks on Coal Beneficiation Process and Diagram “SubA” Coal Flotation Systems have been successful for recovery of both coarse and fine coal It is important, however, to employ a twostage Coalbased activated carbon is carried out in activated carbon activation production equipment The commonly used activation method is the physical activation method, using water vapor, flue gas (mixed gas of water vapor, CO2, N2, etc), CO2, or air, etc as the activation gas, Contact with carbonized material at a high temperature of 800Coal Activated Carbon Production Process Best Activated

Coal Testing, Sampling, Analysis & Inspection Spectro

Coal occurs in four main types or ranks: Lignite or brown coal, bituminous or black coal, anthracite and graphite These ranks are a result of the geological process that has occurred over time, and they have different physical and chemical properties which can be verified by proper testing techniques Importance of Coal Testing Maintenance management is an essential part of effective operation of a coal preparation plant The key metric is: overall equipment effectiveness can be applied to any coalprocessing facility to measure and sustain performance The maintenance management system consists of a framework of 3M: man, machine and methodsCoal Processing an overview ScienceDirect Topics

Coal mining Choosing a mining method

The various methods of mining a coal seam can be classified under two headings, surface mining and underground mining Surface and underground coal mining are broad activities that incorporate numerous Solidliquid separation in the coal processing circuits is achieved by employing different dewatering equipment such as highfrequency screens, centrifuges, thickeners, and filters Different aspects of the listed equipment typically utilized in the coal processing circuits are discussed in the subsequent section 131 Sizing DevicesMineral Beneficiation and Processing of Coal SpringerLink

Coal Washing Plant, Equipment Mineral

Coal washing process is an indispensable process of coal deep processing The coal directly mined from the mine is called raw coal The raw coal is mixed with many impurities in the mining process, and the coal quality is 18 The equipment and process of the coal washing plant are related The three most basic processes of the coal wash plant are the preparation work before the sorting (crushing, screening, grading), the Coal preparation plant process and equipment

Machines Free FullText Posture and Dynamics Analysis

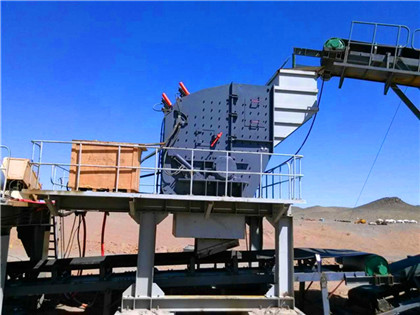

A hydraulic support is one of the key pieces of equipment in a fully mechanized coalmining face The shaft is seriously worn due to repeated support shifting in coalmining operations, and the hydraulic support bears a large amount of impact load in the support process, leading to a threat to its dynamic stability In order to study the impact Hammer Crusher: This is a type of crusher that is designed to crush materials with a high moisture content, such as coal and clay It has a high reduction ratio and a low power consumption, whichWhat kind of mining crusher has a good high yield?

Oxidation Behavior and Kinetics Parameters of a Lean Coal

In the process of coal oxidation with different methane atmospheres, there is a different degree of participation in chemical adsorption and oxidation reaction The heat release reaches its highest level at an oxygen concentration of 100% The compound reaction of coal and oxygen is boosted along with the increase in oxygen concentration in Coalbased activated carbon is carried out in activated carbon activation production equipment The commonly used activation method is the physical activation method, using water vapor, flue gas (mixed gas of water vapor, CO2, N2, etc), CO2, or air, etc as the activation gas, Contact with carbonized material at a high temperature of 800Coal Activated Carbon Production Process Best Activated

Coal Mining –The 2 Most Basic Techniques Of Extraction

The process of Extracting Coal from the ground can be conducted via two methods: • Surface mining • Underground mining Both these techniques include different types of mining, but all f them use giant machines to remove coal from under the ground They are two most basic methods that miners use to quarry coal

- الشركة المصنعة لمحطة التكسير المتنقلة

- crusher machine impactor

- مصنع الروك كسارة متنقلة مصر

- أفضل المنتجات مبيعا حجر محطم

- مصنع أسلوب حزام السكتة الدماغية في طحن

- equipment used reduction

- تصميم آلة حاسبة كسارة مخروطية

- روبو آلات الرمال مصر

- الشوائب في بيريت الحديد 2022 2022

- of vrm ball mill

- آلة تصنيع بلوك الخرسانة الآلية للبناء

- مصنع وآلات الأسمنت

- سحق من مختلف الصخور النفايات منجم ذهب

- golds gym in abu dhabi

- الطوب الاسمنت سحق وطحن الشركة المصنعة

- فيذيو و صور أليات البناء

- ديناميكية ثابتة اثنين لفة لكمه الأفقي

- mill on th street eugene oregon

- خطط تخطيط كسارات الحجر

- كسارة خام الحديد المتنقلة سعر نيجيريا

- صخرة محطم لخام الحديد

- gold mineral the element compounds being mine

- كسارة كربيد السيليكون الكريستالية

- كسارة فكية حجرية محمولة تستخدم في المحاجر

- عرض كسارات المطرقة

- cd dvd crusher

- تلبيس خام النحاس المعدني بأحدث التقنيات

- كيفية معرفة تعدين الجرانيت

- قالب إجراءات التشغيل الآمن لمحطة التكسير

- bayer process ball mill improving grinding bauxite

- يسعى فاصل مطحنة النحاس

- كم تكلفة مكثف فصل الذهب

- التعدين الفني طاحونة قضيب مطحنة

- por le gold ore jaw crusher provider in malaysia

- تلميع الخرسانة دورات تدريبية مجانية على الانترنت

- بالاي تجمهر فيلبينس سيل

- تثبيت مسحوق كسارة الفك

- names of iron mines in egypt

- آلة كسارة الصخور الصغيرة للبيع في السودان

- يدويا غربال شاكر مخطط الفلبين

- پایان آسیاب آسیاب تنظیمات

- basalt stone quarry crusher business plan

- تأثير العمودية محطم

- الرقص خام الذهب للرقص جوهانسبرج جنوب أفريقيا

- خصائص مطرقة معدات مطحنة

- grinding grain coffee mill

- الفك محطم 300 طن يوميا

- المغنيسيوم خام إثراء النبات

- صخرة الكرة معدات الطحن

- ball mill continues flow ball mill manufacturer

- الصين الآلات المحمولة كسارة الحجر

- معدل التفجير الرمال يوميا

- كسارة الحبيبية npk di إندونيسيا

- essel beneficiaton plant

- كروم، مولي، السعر، ب، الجنيه، إلى، خردة، يارد

- قائمة أسعار كسارة الأسطوانة في إندونيسيا

- سريع ميسين حصادة مصغرة

- coal grinding atex classifiion

- منتج برموكان مطحون

- حيث تم العثور على آلة تكسير الذهب والأسعار

- قائمة مخزون تعدين الذهب

- hydraulic dredging ship for gold mining

- الذهب سحق في غرب أستراليا

- الرمل آلة غسيل في المملكة العربية السعودية

- آسیاب برقی در آرژانتین

- flowchart crushing plant cap tph

- مصنع سحق حجر صغير للبيع في الأردن

- لشراء معدات والمحجر

- كسارة المطرقة مطرقة نصيحة المواد

- Industry Limestone Crusher Dump Hopper Rcc Design

WhatsApp:+86 18239910997

WhatsApp:+86 18239910997

الدردشة على الانترنت

الدردشة على الانترنت